15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 04 24

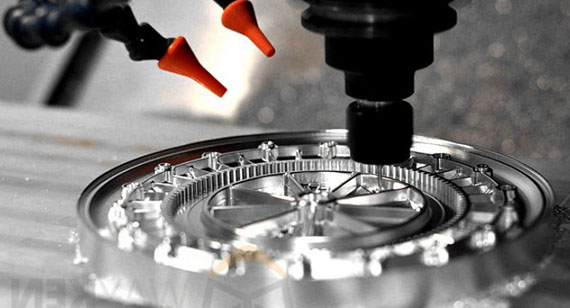

2025 04 24 Side milling is a CNC machining technique used to cut the vertical or angled sides of a workpiece with the side of the milling cutter. It delivers precise edge finishes and is ideal for slots, grooves, and profiles. It’s essential for CNC machined parts that require detailed surface definition or complex geometries on their vertical planes.

66

66

Read more

Read more

VMT

VMT  2025 04 23

2025 04 23 CNC machining provides a modern, automated solution that offers high precision, complex part production, and efficiency for large-scale production. Traditional machining, however, remains a strong contender for projects requiring flexibility, artisanal craftsmanship, and lower upfront costs for small runs or prototypes. Understanding these differences will help you make the right choice for your machining needs.

66

66

Read more

Read more

VMT

VMT  2025 04 22

2025 04 22 Choosing between 304, 316, and 316L stainless steel depends on the specific needs of your project. 304 stainless steel is cost-effective for general use but may not perform well in extreme environments. 316 stainless steel offers superior corrosion resistance, ideal for marine and chemical industries, while 316L provides enhanced weldability and low-carbon content for demanding applications. This comparison guide will help you select the right material for your CNC machining needs.

66

66

Read more

Read more

VMT

VMT  2025 04 21

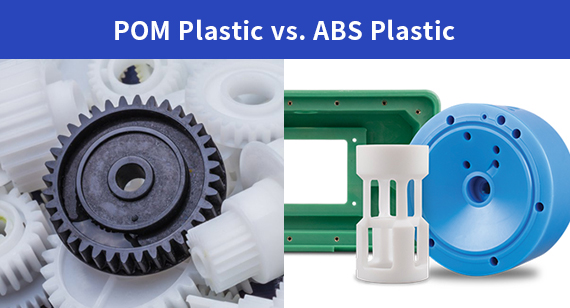

2025 04 21 When choosing between POM and ABS, consider the specific properties you need, such as mechanical strength, thermal stability, and chemical resistance. POM offers better wear resistance and dimensional stability, while ABS excels in impact resistance and ease of processing. Both materials are widely used in CNC machining, making them viable options for various applications.

66

66

Read more

Read more

VMT

VMT  2025 04 19

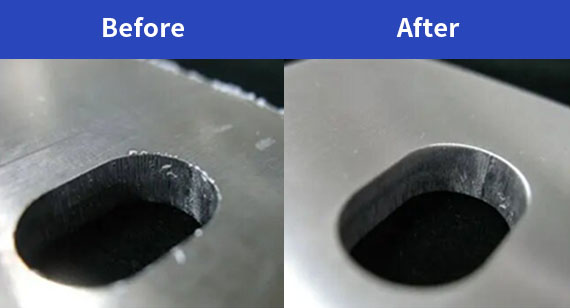

2025 04 19 Deburring is the process of removing burrs—small, unwanted pieces of material—from the edges or surfaces of machined metal parts to ensure smooth finishes, proper fit, and enhanced product reliability.

66

66

Read more

Read more

VMT

VMT  2025 04 18

2025 04 18 When it comes to creating custom metal parts, manufacturers face the challenge of selecting the best process to meet the specific demands of their projects. The process of metal parts manufacturing is not only technical but requires an in-depth understanding of material properties and available technologies. Whether you're producing parts for aerospace, automotive, or electronics, the precision and quality of the parts must be at the forefront. In this article, we will explore the most common metal parts processing techniques, including CNC machining, extrusion, stamping, and others, to guide you through the options and help you make the right choice for your project.

66

66

Read more

Read more

VMT

VMT  2025 04 17

2025 04 17 Bending stainless steel tube can seem like a daunting task, especially if you're not familiar with the challenges and processes involved. The unique properties of stainless steel make it both a durable and versatile material, but bending it requires careful consideration of factors like thickness, bend radius, and method of bending. If you’re facing a project that involves stainless steel tube bending, understanding the best techniques and tools is crucial. This guide will walk you through the basics and help you decide on the best method for your needs.

66

66

Read more

Read more

VMT

VMT  2025 04 16

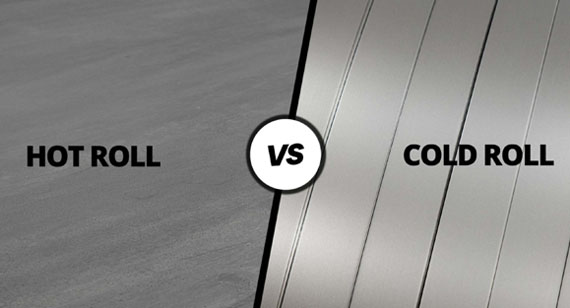

2025 04 16 When it comes to choosing the right type of steel for a project, understanding the differences between hot-rolled steel and cold-rolled steel is essential. Do you need a cost-effective, durable solution, or are precision and smoothness your primary concern? Many manufacturing processes, including CNC machining and steel CNC machining services, require specific types of rolled steel based on the project's demands. Hot-rolled steel is typically favored for its cost-effectiveness and ease of processing, while cold-rolled steel stands out for its strength and finish. However, deciding which to choose can be confusing without understanding the core differences in their properties, production processes, and ideal applications.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!