15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 03 05

2025 03 05 When selecting aluminum for CNC machining, aerospace, automotive, or structural applications, the choice between 7075 aluminum and 6082 aluminum is critical. Both alloys offer unique benefits, but which one is better suited for your needs?

66

66

Read more

Read more

VMT

VMT  2025 03 04

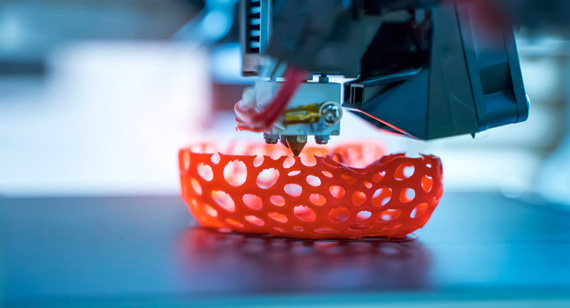

2025 03 04 3D printing has revolutionized the manufacturing industry, offering a cost-effective, flexible, and rapid way to produce prototypes and functional parts. Whether you're an individual looking for custom 3D-printed parts or a business seeking CNC prototype machining, understanding 3D printing service costs is essential for making an informed decision.

66

66

Read more

Read more

VMT

VMT  2025 03 03

2025 03 03 Metal plays an essential role in manufacturing, engineering, and everyday life. From structural components to high-tech devices, metals are the foundation of countless industries. However, not all metals are created equal. When selecting materials for CNC machining, casting, or industrial applications, the choice between ferrous and non-ferrous metals significantly impacts performance, durability, and cost.

66

66

Read more

Read more

VMT

VMT  2025 03 02

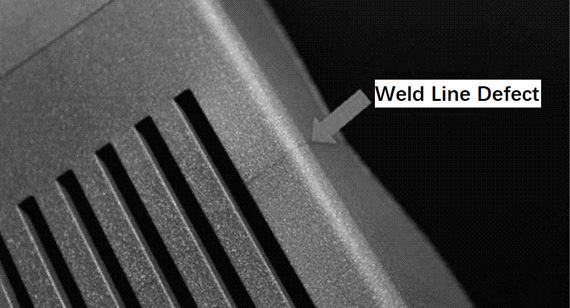

2025 03 02 Weld lines in injection molding can be a critical defect, affecting both aesthetic appeal and mechanical strength. These lines occur when two or more molten plastic flows meet but do not fully fuse, creating a visible seam or weakness in the finished product. This defect can result in structural integrity issues, reduced impact resistance, and visual imperfections that lower product quality.

66

66

Read more

Read more

VMT

VMT  2025 03 01

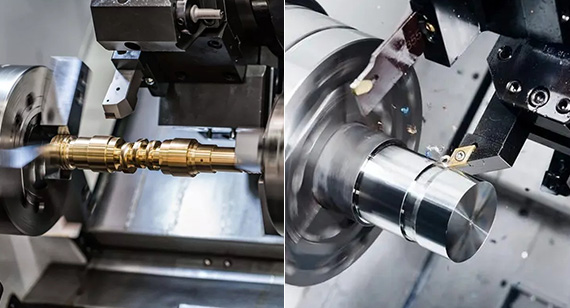

2025 03 01 Choosing between a CNC lathe and a CNC turning center can be challenging, especially if you're unsure how they differ. Many manufacturers and CNC machining professionals use these terms interchangeably, but in reality, they have distinct capabilities, applications, and advantages.

66

66

Read more

Read more

VMT

VMT  2025 02 28

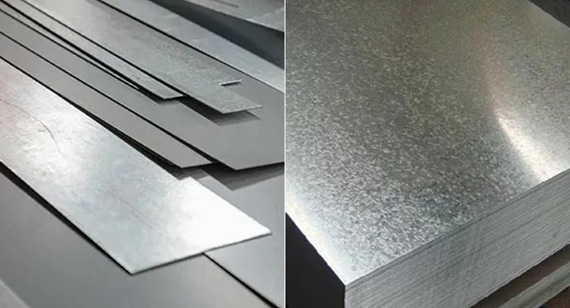

2025 02 28 Choosing the right steel coating can be challenging, especially when deciding between galvanneal vs. galvanized. Both materials provide corrosion resistance and durability, but they differ in composition, finish, and applications. If you're involved in CNC machining, custom CNC machining, or industrial fabrication, selecting the best option is crucial for optimizing performance and longevity.

66

66

Read more

Read more

VMT

VMT  2025 02 27

2025 02 27 There are 10 major methods for plastic welding, each with its own set of advantages. These techniques include ultrasonic welding, laser welding, friction welding, and more. Understanding which welding method is best suited for your application—whether for plastic welding CNC machining parts or custom CNC machining projects—can help streamline the process and improve the final result. Continue reading to discover each method and how it can benefit your projects.

66

66

Read more

Read more

VMT

VMT  2025 02 26

2025 02 26 Laser cutting aluminum is becoming an increasingly popular method for manufacturers and designers looking to create precise, intricate, and high-quality parts. If you're involved in CNC machining, you may already know that aluminum presents certain challenges due to its thermal properties and reflective nature. But what if there was a way to achieve flawless, efficient cuts, even with these challenges? Laser cutting might be the perfect solution. In this article, we will break down how laser cutting aluminum works, the various machine options available, and why it’s considered a game-changer in CNC machining.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!