15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 02 07

2025 02 07 Choosing the right metal for your CNC machining parts can be overwhelming. Brass, aluminum, and stainless steel each have unique advantages and drawbacks, influencing performance, durability, and cost. Selecting the wrong material can lead to machining difficulties, poor product performance, or unnecessary expenses.

66

66

Read more

Read more

VMT

VMT  2025 02 06

2025 02 06 In the world of CNC machining, VMT is recognized for its innovative solutions in custom CNC machining, prototype machining, and CNC milling services. However, as the manufacturing landscape evolves, more competitors and alternatives emerge, offering similar services with unique advantages. In this article, we will explore the top 12 VMT alternatives and competitors for 2025. Whether you're looking for better pricing, faster turnaround, or specialized capabilities, there is a solution tailored to your needs.

66

66

Read more

Read more

VMT

VMT  2025 02 05

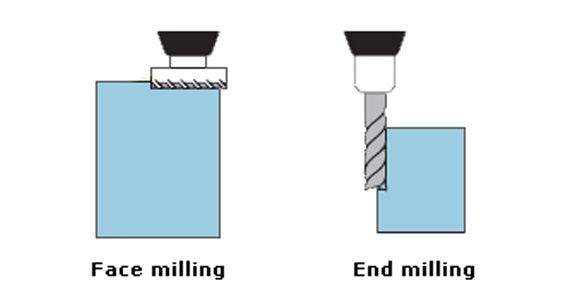

2025 02 05 When it comes to precision machining, choosing the right milling process is critical for achieving desired results. The distinction between face milling and end milling plays a vital role in selecting the appropriate technique for your project. Both processes are fundamental in CNC machining, but their applications and advantages differ significantly. If you’ve ever found yourself wondering which process is best for your CNC milled parts or custom CNC milling, this guide will help you understand the key differences between face milling and end milling, as well as when and why to use them.

66

66

Read more

Read more

VMT

VMT  2025 02 04

2025 02 04 Face milling is a critical machining operation used extensively in manufacturing for producing smooth, flat surfaces. But how does it work? What are its advantages and limitations? And why should you consider face milling for your next CNC project? If you're wondering how this technique can improve the precision of your CNC milled parts, you've come to the right place. In this article, we will delve into the details of face milling, its applications, and how to make the most of it for your custom CNC milling needs.

66

66

Read more

Read more

VMT

VMT  2025 02 03

2025 02 03 Mechanical testing in manufacturing evaluates key material properties, such as strength, ductility, and hardness, to ensure the quality and reliability of products. Methods like tensile testing, hardness testing, and fatigue testing are employed to simulate real-world conditions. By selecting the right mechanical test, manufacturers can avoid material failure, ensure safety, and comply with industry standards.

66

66

Read more

Read more

VMT

VMT  2025 02 02

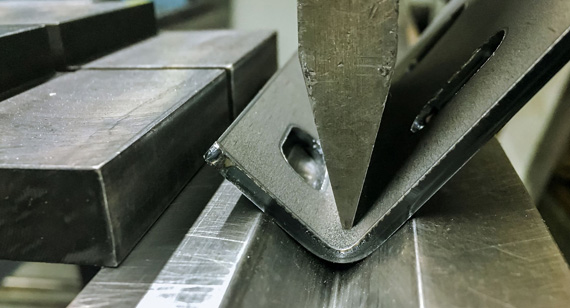

2025 02 02 Sheet metal bending is a vital process in manufacturing that involves reshaping metal sheets by applying force. The process is used to create a wide variety of shapes and structures needed in industries ranging from automotive to aerospace. But like any advanced manufacturing technique, sheet metal bending requires precision, knowledge of materials, and the right machinery. If you're in the business of CNC machining or manufacturing, understanding sheet metal bending and its best practices can improve the quality, efficiency, and cost-effectiveness of your projects.

66

66

Read more

Read more

VMT

VMT  2025 02 01

2025 02 01 The automotive industry relies heavily on fasteners to secure and assemble parts, ensuring that vehicles run safely and efficiently. From simple screws to specialized rivets, automotive fasteners play a pivotal role in connecting components, and understanding their types and functions is essential for both manufacturers and automotive engineers. However, with so many options available, choosing the right fastener for specific automotive applications can be complex and daunting. In this article, we will guide you through the various types of fasteners used in automotive manufacturing and offer insights on when and why to use them.

66

66

Read more

Read more

VMT

VMT  2025 01 31

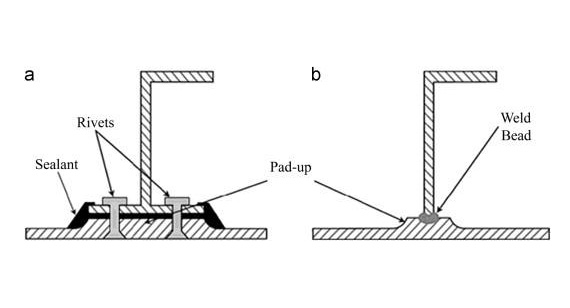

2025 01 31 When deciding between riveting vs. welding, consider factors like material type, required strength, and cost. Riveting is quick and cost-effective but offers lower joint strength, while welding provides strong, permanent connections but requires specialized equipment and skills. Your choice will depend on your project’s specific needs and constraints.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!