15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 01 22

2025 01 22 Low carbon steel, often called mild steel, has historically been one of the most commonly utilized metals due to its affordability, ease of fabrication, and moderate mechanical properties. Stainless steel, a more recent development, contains chromium and other alloying elements that confer superior corrosion resistance and enhanced strength for specialized applications. As the manufacturing industry increasingly embraces advanced **custom CNC machining** techniques, understanding how these two materials differ in composition, formability, surface finish, and cost can significantly impact project outcomes. By thoroughly exploring mild steel and stainless steel, designers and procurement specialists can select the best fit for their components, ensuring that quality, durability, and budget goals are properly aligned.

66

66

Read more

Read more

VMT

VMT  2025 01 21

2025 01 21 To oxidize brass using antique methods, the key steps involve cleaning the brass thoroughly, choosing an appropriate oxidation technique—such as chemical patinas, heat treatments, or natural weathering—and then sealing the final finish. First, remove all oils, oxides, and residues to ensure the brass surface is free of contaminants. Next, select your preferred oxidation method: chemical solutions can deliver quick, controlled patinas; thermal oxidation relies on heat and oxygen exposure to darken the metal; natural patina methods require time and exposure to weather; household items like vinegar and salt can create a gentle patina; and commercial brass oxidizers are designed for consistent, predictable results. Finally, once you’ve achieved your desired antique look, apply a protective topcoat—like wax, lacquer, or powder coating—to preserve the finish and protect against further corrosion. By following these essential steps, you can confidently transform brand-new brass surfaces into vintage showstoppers.

66

66

Read more

Read more

VMT

VMT  2025 01 20

2025 01 20 When deciding between brass and steel for CNC machining projects, focus on key factors like corrosion resistance, strength, machinability, weight, and cost. Brass is known for its excellent corrosion resistance, lower melting point, and attractive appearance, making it ideal for decorative and low-friction applications. Steel, on the other hand, provides higher tensile strength, increased durability, and strong structural integrity. If you need parts that can withstand heavy loads and harsh conditions, steel might be your best bet. However, if you desire easier machining, better electrical conductivity, or a stylish finish, brass could be the metal for you. Evaluating your project’s specific requirements will help you decide if brass or steel is the right choice.

66

66

Read more

Read more

VMT

VMT  2025 01 19

2025 01 19 Before you commit to either brass or stainless steel, it’s helpful to grasp what each metal truly brings to the table. Both are incredibly popular in multiple industries, including construction, electronics, and decorative goods. But they differ in core ways—like composition, cost, and how easily they can be formed or machined. With the right knowledge, you can select the material that best fits your use case, saving time, money, and potential frustration in the long run.

66

66

Read more

Read more

VMT

VMT  2025 01 18

2025 01 18 Brass vs. aluminum represents a classic debate in manufacturing. Both are non-ferrous metals, each offering distinct benefits like corrosion resistance, malleability, and a variety of surface finishes. Yet they differ in key ways—chemical makeup, mechanical properties, cost, and typical uses. Before you settle on brass CNC machining parts or aluminum CNC machining parts, it’s crucial to understand these differences. This overview sets the stage for the detailed sections ahead, ensuring you have the knowledge to pick the right material for your specific design, budget, and performance requirements.

66

66

Read more

Read more

VMT

VMT  2025 01 17

2025 01 17 Aluminum and steel are two of the most widely used metals in the manufacturing realm, particularly for CNC machining parts that span industries such as aerospace, automotive, construction, consumer electronics, and more. Each metal possesses distinct characteristics—ranging from tensile strength and ductility to corrosion resistance and thermal conductivity—that make it uniquely suited for specific tasks. While aluminum is praised for its light weight and corrosion resistance, steel has remained the backbone of heavy-duty structures and machinery for centuries. Understanding the core contrasts between these two metals is critical for anyone seeking custom CNC machining solutions.

66

66

Read more

Read more

VMT

VMT  2025 01 16

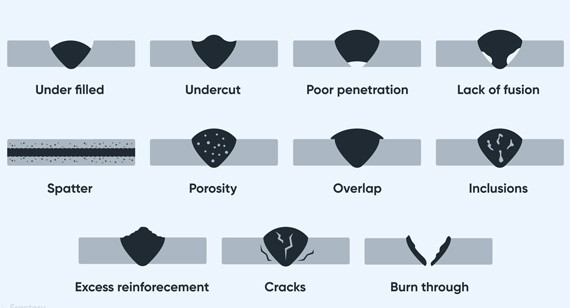

2025 01 16 Welding defects can significantly impact the quality and durability of CNC machining parts. By identifying and addressing these defects early, you can enhance the reliability of your products and reduce production costs. Whether you’re involved in CNC prototype machining or large-scale manufacturing, this guide provides valuable insights into the most prevalent welding defects and how to resolve them effectively.

66

66

Read more

Read more

VMT

VMT  2025 01 15

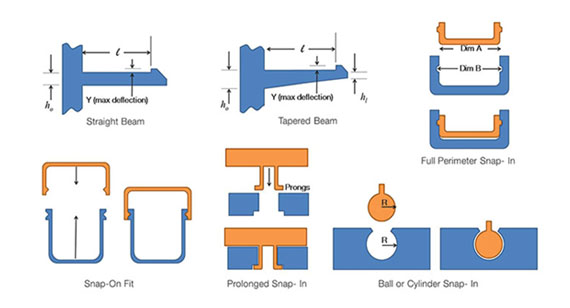

2025 01 15 Snap-fit joints are integral to modern manufacturing, offering a reliable and efficient method for assembling parts without the need for additional hardware. By leveraging the right snap-fit design and materials, you can improve the durability and functionality of your CNC machining parts, whether you’re engaged in custom CNC machining, working in a CNC machining factory, or handling CNC prototype machining. This guide will provide you with a clear understanding of snap-fit joints, helping you make informed decisions that enhance your CNC machining services and overall product quality.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!