15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 12 29

2024 12 29 Effective CNC machining parts design involves adhering to best practices such as designing with appropriate tool sizes, maintaining optimal cavity depths, considering machine axis limitations, and avoiding excessively small features. By following these guidelines, you can ensure your designs are machinable, cost-efficient, and produce high-quality parts consistently.

66

66

Read more

Read more

VMT

VMT  2024 12 28

2024 12 28 Polishing anodized aluminum involves cleaning, evaluating the surface condition, selecting appropriate tools and materials, and applying specific polishing techniques. Methods such as hand polishing, mechanical polishing, and using specialized polishes ensure a smooth, shiny finish while preserving the anodized layer. Proper preparation and post-care are essential for maintaining polished anodized aluminum.

66

66

Read more

Read more

VMT

VMT  2024 12 27

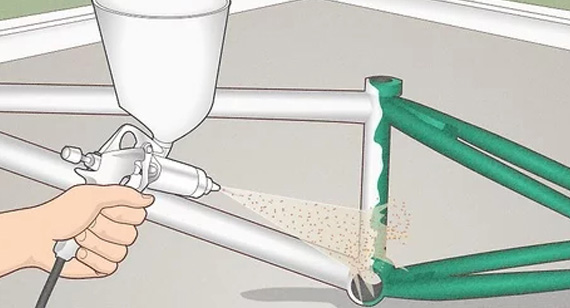

2024 12 27 Removing powder coating from aluminum can be achieved through various methods, including thermal stripping, chemical stripping, sandblasting, and laser removal. Each method offers distinct advantages and is suitable for different applications, ensuring effective restoration of aluminum CNC machined parts without damaging their integrity.

66

66

Read more

Read more

VMT

VMT  2024 12 26

2024 12 26 Steel can be anodized through specialized processes that enhance its corrosion resistance and surface hardness. While more complex and costly than anodizing aluminum, steel anodizing offers improved durability and aesthetic finishes. Understanding the process and benefits of steel anodizing helps manufacturers decide whether it suits their CNC machining needs.

66

66

Read more

Read more

VMT

VMT  2024 12 25

2024 12 25 When comparing anodized aluminum vs. anodized steel, anodized aluminum generally emerges as the more cost-effective choice due to lower material costs and easier machining processes. However, the final decision should consider factors like application requirements, durability, and specific CNC machining services to ensure optimal performance and cost efficiency.

66

66

Read more

Read more

VMT

VMT  2024 12 24

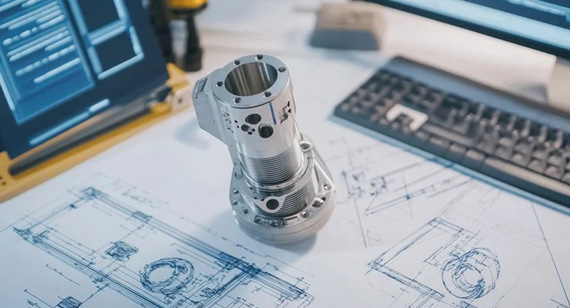

2024 12 24 Engineering design is a methodical approach used to develop functional products and systems that solve specific problems or fulfill particular needs. It involves applying scientific principles, creativity, and technical knowledge to conceive, design, and produce products that are efficient, reliable, and cost-effective. The engineering design process encompasses various stages, including problem identification, research, concept development, prototyping, testing, and final production.

66

66

Read more

Read more

VMT

VMT  2024 12 23

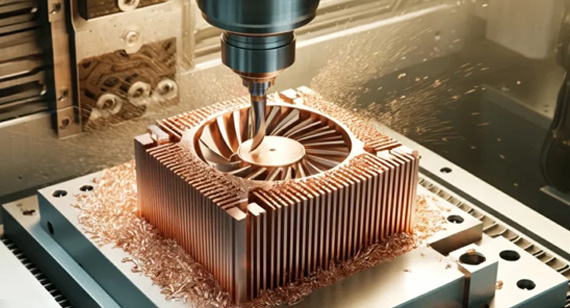

2024 12 23 Copper machining refers to the process of shaping copper and its alloys into precise and intricate parts using CNC (Computer Numerical Control) machines. Unlike conventional machining methods, Copper CNC Machining employs advanced CNC lathes and milling machines equipped with specialized tools designed to handle the unique properties of copper. This method ensures high accuracy, smooth surface finishes, and the ability to produce complex geometries that are difficult to achieve with traditional machining techniques.

66

66

Read more

Read more

VMT

VMT  2024 12 22

2024 12 22 Swiss machining is a specialized CNC machining process designed to produce highly precise and complex parts with exceptional accuracy and surface finish. Unlike conventional CNC lathes, Swiss machining employs a sliding headstock that supports the workpiece close to the cutting tool, minimizing deflection and vibration during the machining process. This unique setup allows for the production of small, intricate components with tight tolerances, making Swiss machining ideal for industries such as medical devices, aerospace, electronics, and watchmaking.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!