15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 01 06

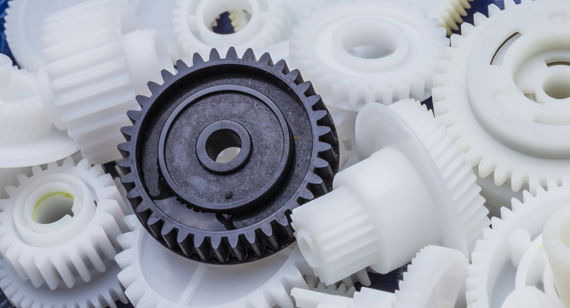

2025 01 06 Choosing the appropriate material is a critical step in the CNC machining manufacturing process. To determine whether Polyoxymethylene or Delrin is the better fit for your project, it is essential to explore their respective compositions, properties, and applications. This comprehensive guide delves into the intricacies of POM and Delrin, providing manufacturers with the knowledge needed to make strategic decisions that enhance the performance and quality of their CNC machined parts.

66

66

Read more

Read more

VMT

VMT  2025 01 05

2025 01 05 Electroplated copper is a vital process in CNC machining, providing enhanced conductivity, corrosion resistance, and surface finish to machined parts. By applying a thin layer of copper through electrochemical means, manufacturers can significantly improve the performance and durability of their components, making copper electroplating a standard solution for a variety of industrial applications.

66

66

Read more

Read more

VMT

VMT  2025 01 04

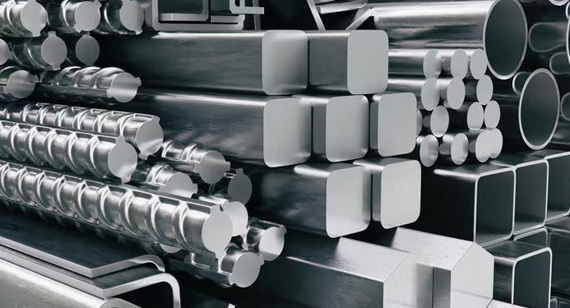

2025 01 04 In the realm of CNC machining parts manufacturing, the selection of the appropriate steel material is paramount. Alloy steel and stainless steel are two of the most commonly used materials, each with its distinct characteristics and advantages. This guide aims to provide a detailed comparison between these two steel types, helping manufacturers, engineers, and designers make informed decisions based on their specific needs and applications. By understanding the composition, properties, and applications of alloy steel and stainless steel, you can enhance the quality, durability, and performance of your CNC machined parts.

66

66

Read more

Read more

VMT

VMT  2025 01 03

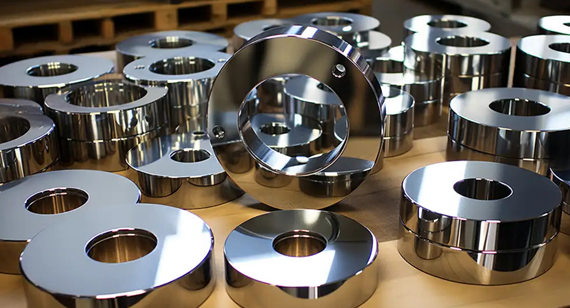

2025 01 03 When deciding between electrolytic polishing and mechanical polishing for your CNC machined parts, consider factors such as surface finish quality, production volume, material compatibility, and cost-effectiveness. Electrolytic polishing offers superior corrosion resistance and a mirror-like finish, making it ideal for high-precision applications, while mechanical polishing provides versatility and eco-efficiency, suitable for a wide range of materials and part complexities.

66

66

Read more

Read more

VMT

VMT  2025 01 02

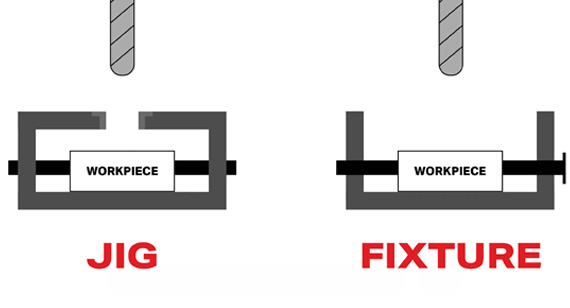

2025 01 02 For CNC acrylic machining parts, use sharp carbide cutters with moderate feed rates to prevent melting and chipping. Set optimal spindle speeds (8,000–15,000 rpm) and apply effective coolants or air blasts to dissipate heat. Securing workpieces firmly with a stable CNC machining fixture design further enhances cut quality and prevents distortion, ensuring polished, dimensionally accurate PMMA components.

66

66

Read more

Read more

VMT

VMT  2025 01 01

2025 01 01 Clamps and fixtures are specialized workholding devices used in CNC machining to securely hold, support, and position parts. Clamps apply pressure to prevent movement, while fixtures provide a stable framework to guide tools and ensure precise alignment. Mastering fixture and clamp design boosts production efficiency, reduces setup times, and guarantees consistent quality across CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2024 12 31

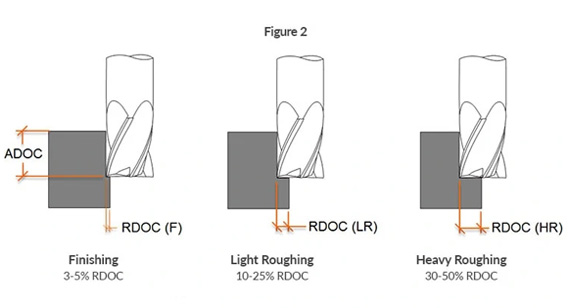

2024 12 31 The depth of cut in machining refers to the measurement between the uncut surface and the newly formed surface after a cutting pass. Properly defining and calculating the cutting depth enhances tool life, reduces heat buildup, and yields precise CNC machining parts. By following recommended guidelines, you can streamline custom CNC machining operations, minimize errors, and achieve uniform results in CNC prototype machining and full-scale production.

66

66

Read more

Read more

VMT

VMT  2024 12 30

2024 12 30 CNC machining for the automotive industry leverages computer-controlled machines to produce automotive CNC machining parts with exceptional precision and repeatability. Key advantages include higher production speed, automation, repeatability, accuracy, design flexibility, multi-material support, customization, and consistent quality. These benefits significantly enhance manufacturing efficiency and the overall performance of CNC machining parts in automotive applications.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!