15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 01 14

2025 01 14 Selecting the appropriate spring type and material is essential for achieving the desired functionality and longevity of your products. By understanding the different types of springs, their specific applications, and the materials used in their manufacturing, you can make informed decisions that enhance the performance and reliability of your CNC machining parts. Whether you’re involved in custom CNC machining, working in a CNC machining factory, or handling CNC prototype machining, this guide will equip you with the knowledge needed to optimize your spring selection and manufacturing processes.

66

66

Read more

Read more

VMT

VMT  2025 01 13

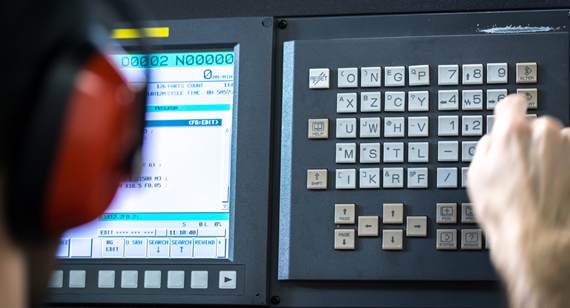

2025 01 13 G and M codes are the backbone of CNC machining programming, serving as the instructions that guide your machines to perform precise movements and operations. By understanding these codes, you can enhance the performance of your CNC machining services, whether you're working in a CNC machining factory, handling CNC prototype machining, or managing custom CNC machining projects. Mastering G and M codes ensures that your CNC machines operate smoothly, producing high-quality parts consistently and efficiently.

66

66

Read more

Read more

VMT

VMT  2025 01 12

2025 01 12 An alloy is a combination of two or more elements, typically metals, that are fused together to create a material with enhanced properties. By blending different metals, alloys can achieve superior strength, corrosion resistance, and other desirable characteristics that pure metals often lack. This makes alloys indispensable in various industries, from automotive and aerospace to medical devices and electronics. Understanding what alloys are and how they work is crucial for anyone involved in CNC machining, as it allows for the creation of custom CNC machining parts that meet exact specifications and performance standards.

66

66

Read more

Read more

VMT

VMT  2025 01 11

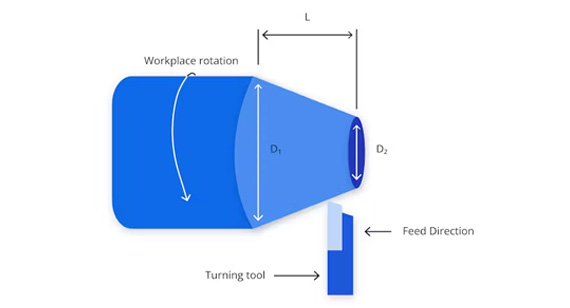

2025 01 11 Taper turning in CNC machining involves creating a gradual slope or angle on a workpiece using specialized techniques and tools. This process ensures that parts fit together seamlessly, providing both aesthetic appeal and functional precision. By mastering taper turning, CNC turning factories can produce high-quality, custom CNC turning parts with enhanced stability and performance.

66

66

Read more

Read more

VMT

VMT  2025 01 10

2025 01 10 A taper in CNC machining refers to a gradual narrowing or widening of a tool or workpiece, ensuring secure tool placement, precise machining, and efficient operations. By incorporating tapers, CNC machining shops can achieve better stability, reduce vibrations, and streamline tool changes, ultimately leading to higher quality parts and increased efficiency.

66

66

Read more

Read more

VMT

VMT  2025 01 09

2025 01 09 Selecting the appropriate method to remove the anodized layer on aluminum is crucial for maintaining the integrity and functionality of your CNC machining parts. This guide will walk you through the characteristics of anodized aluminum, reasons for removal, safety precautions, various removal methods, and tips for choosing the best approach for your specific applications. By understanding these aspects, you can effectively manage the anodizing process and ensure the quality and longevity of your aluminum components.

66

66

Read more

Read more

VMT

VMT  2025 01 08

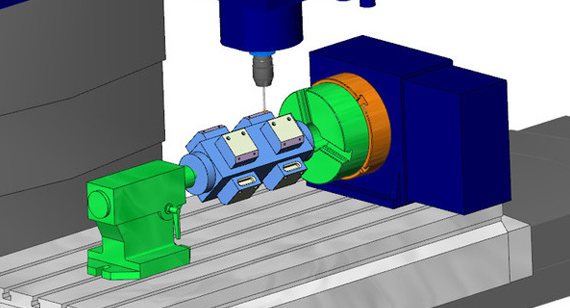

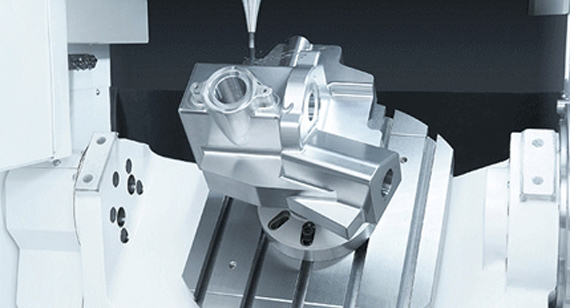

2025 01 08 4-axis CNC machining is an advanced method that adds an extra rotational axis to traditional 3-axis machines, allowing for more complex and precise manufacturing. This extra movement enhances the flexibility and accuracy of CNC machining parts, making it a valuable option for custom CNC machining and CNC machining services.

66

66

Read more

Read more

VMT

VMT  2025 01 07

2025 01 07 Choosing the right CNC machining technology is crucial for achieving optimal results in your manufacturing projects. To effectively leverage the benefits of 4-axis and 5-axis CNC machining, it is essential to explore their functionalities, advantages, limitations, and applications. This comprehensive guide delves into the intricacies of 4-axis and 5-axis CNC machining, providing manufacturers with the insights needed to make informed decisions that enhance the quality and efficiency of their CNC machined parts.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!