15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 01 30

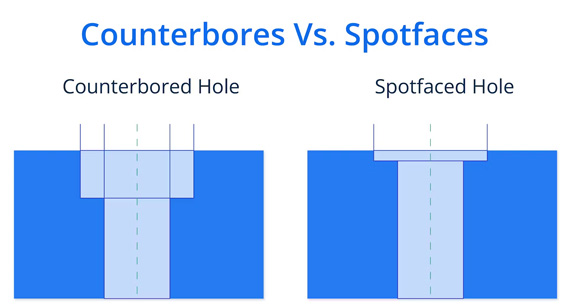

2025 01 30 When it comes to machining and manufacturing, precision is key. Whether you’re working on CNC parts or custom machining, the choice between countersinks and counterbores can significantly affect the performance and appearance of the finished product. Both hole types are used for specific purposes, yet they are often confused due to their similar appearance. How do they differ, and when should each be used? Understanding the differences between countersinks and counterbores is crucial for any machinist or engineer looking to optimize their machining processes and designs. In this article, we will break down what each term means, explore their unique applications, and help you make informed decisions for your CNC machining needs.

66

66

Read more

Read more

VMT

VMT  2025 01 29

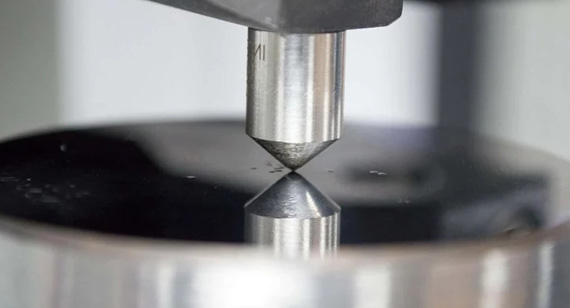

2025 01 29 Material hardness is a measure of a material's resistance to deformation, scratching, or indentation. It is a critical factor when choosing materials for CNC machining parts, as it influences the wear resistance, durability, and overall performance of the final product. To ensure you select the right material, it's important to understand how hardness is tested and what different hardness tests can tell you about your material’s performance.

66

66

Read more

Read more

VMT

VMT  2025 01 28

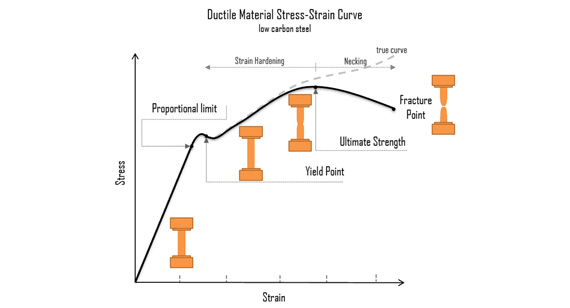

2025 01 28 When it comes to selecting materials for engineering, manufacturing, or CNC machining, understanding the difference between stiffness and strength is crucial. These two properties are often confused but serve very different functions. Both are key to ensuring the performance and durability of parts, but knowing when to prioritize one over the other can impact the design process. In this article, we’ll explore the distinctions between stiffness and strength, how they influence material selection, and why getting the balance right is essential for optimal performance in CNC machining and beyond.

66

66

Read more

Read more

VMT

VMT  2025 01 27

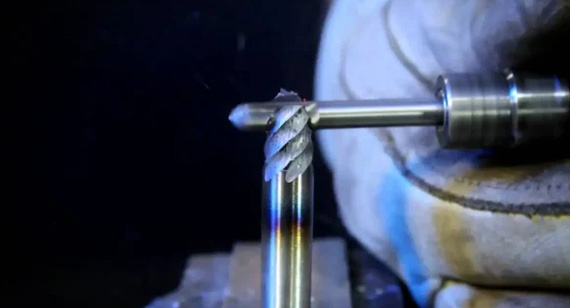

2025 01 27 Removing a broken tap requires the right tools and techniques, such as using tap extractors, drilling, or even utilizing EDM machines. It's critical to understand why taps break and how to prevent it from happening. This guide covers the most effective methods and tips for removing broken taps, making it essential reading for CNC machining professionals.

66

66

Read more

Read more

VMT

VMT  2025 01 26

2025 01 26 In this article, we’ll dive into the science behind titanium's corrosion resistance, its properties, and its applications. By the end, you’ll have a clear understanding of titanium’s rust resistance and why it remains one of the most versatile and reliable materials in modern industries.

66

66

Read more

Read more

VMT

VMT  2025 01 25

2025 01 25 While surgical steel is a type of stainless steel, it’s engineered for specialized medical applications, offering enhanced corrosion resistance and hypoallergenic properties. Stainless steel, in general, is used for a wide range of applications, from household products to heavy-duty machinery. When you need precision CNC machining for parts like surgical steel CNC machining parts or stainless steel CNC machining parts, understanding the differences is key to getting the best results.

66

66

Read more

Read more

VMT

VMT  2025 01 24

2025 01 24 Copper is ideal for applications requiring excellent electrical and thermal conductivity, while steel is best for heavy-duty structural and industrial applications where strength and durability are critical. When deciding between copper vs. steel, consider factors like cost, application, and required properties. CNC machining services can help tailor these metals to meet your project’s unique needs.

66

66

Read more

Read more

VMT

VMT  2025 01 23

2025 01 23 When selecting materials for custom CNC machining projects, two of the most commonly considered metals are titanium and stainless steel. However, understanding the key differences between these two alloys can be challenging, especially when it comes to

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!