15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 02 17

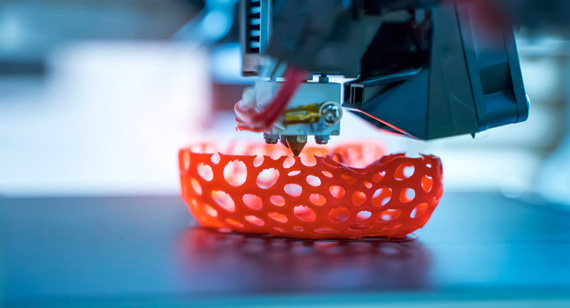

2025 02 17 3D printing prototyping is an efficient way to bring product designs to life quickly. It reduces lead times and cuts costs by allowing designers to create prototypes directly from CAD files without the need for expensive molds or tooling. It is revolutionizing industries like aerospace, healthcare, automotive, and more. Rapid prototyping with 3D printing not only speeds up product development but also helps refine designs before mass production.

66

66

Read more

Read more

VMT

VMT  2025 02 14

2025 02 14 A surface roughness chart is an essential reference in CNC machining that helps engineers measure and control the texture of machined surfaces. By understanding terms like Ra, Rz, and RMS, machinists can achieve the desired surface finish to enhance product performance, aesthetics, and function. This chart ensures consistency and precision in your CNC machining services and helps to choose the correct surface roughness for specific manufacturing needs.

66

66

Read more

Read more

VMT

VMT  2025 02 13

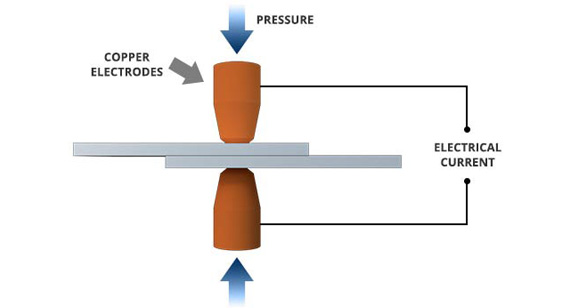

2025 02 13 Spot welding is a process that uses heat generated by electrical resistance to join two metal sheets together at a specific point. Unlike traditional welding methods that rely on an open flame, spot welding focuses on creating localized heat, making it ideal for joining thin metal sheets quickly and effectively. During the process, electrical current passes through the metal workpieces, generating heat at the contact points where the metal is fused together.

66

66

Read more

Read more

VMT

VMT  2025 02 12

2025 02 12 Fasteners are the backbone of countless industries, from construction and automotive to aerospace and heavy machinery. Choosing the right fastener material is critical for ensuring strength, durability, and corrosion resistance. Stainless steel fasteners stand out due to their exceptional resistance to rust, high tensile strength, and long lifespan.

66

66

Read more

Read more

VMT

VMT  2025 02 11

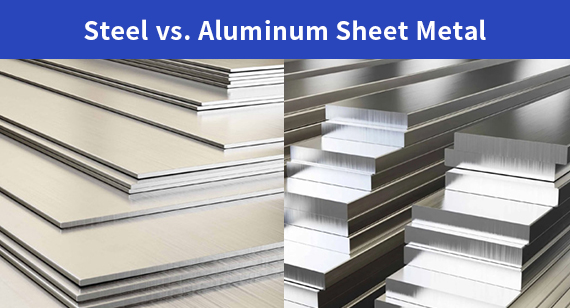

2025 02 11 When it comes to choosing between galvanized steel and aluminum, understanding the key differences is essential for making an informed decision. Both materials offer unique advantages and drawbacks depending on the application. The weight, strength, corrosion resistance, and cost of each metal can have a significant impact on your project's outcome. This article breaks down the major differences between these two materials and explores how their properties affect their suitability for various uses. By understanding these key factors, you can select the best material for your needs, whether you're working on custom CNC machining or larger structural projects.

66

66

Read more

Read more

VMT

VMT  2025 02 10

2025 02 10 When choosing the right material for your project, steel and aluminum are two common choices that often leave manufacturers wondering which one to pick. Both materials offer distinct benefits, but how do you know which one is best suited for your specific needs? In this article, we’ll dive into a direct comparison between steel and aluminum plates to help you understand the key differences, making it easier for you to select the perfect material for your parts. Whether you’re concerned about strength, weight, cost, or durability, we have the answers you need.

66

66

Read more

Read more

VMT

VMT  2025 02 09

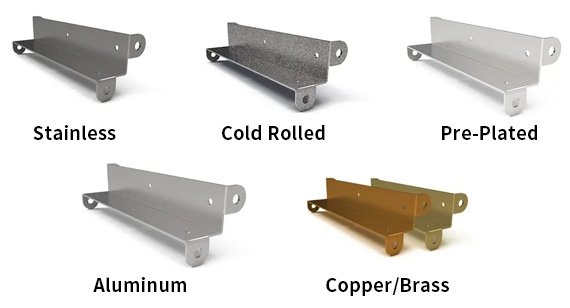

2025 02 09 When choosing the right material for a project, understanding the unique properties of steel, aluminum, and brass metal plates is crucial. Each material offers distinct benefits depending on the application, but how do you choose the right one for your project? Whether you’re manufacturing CNC machining parts or designing custom CNC machining solutions, the decision can significantly impact the overall performance, cost, and longevity of your components. In this article, we’ll break down the key differences between steel, aluminum, and brass to help you make an informed choice.

66

66

Read more

Read more

VMT

VMT  2025 02 08

2025 02 08 When selecting automotive bolts and screws, it's important to consider their function, design, and material. CNC machining services offer high-precision production of automotive bolts and screws, including custom CNC machining for unique or complex designs. By choosing the right material and manufacturing method, you ensure your fasteners deliver long-lasting performance in your vehicle.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!