15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 03 18

2025 03 18 Aluminum alloys are widely used in various industries due to their excellent strength-to-weight ratio, corrosion resistance, and machinability. Among these, 7075 aluminum stands out as one of the strongest aluminum alloys, often compared to mild steel in terms of strength. It is a high-strength, heat-treatable alloy primarily used in aerospace, automotive, and structural applications.

66

66

Read more

Read more

VMT

VMT  2025 03 17

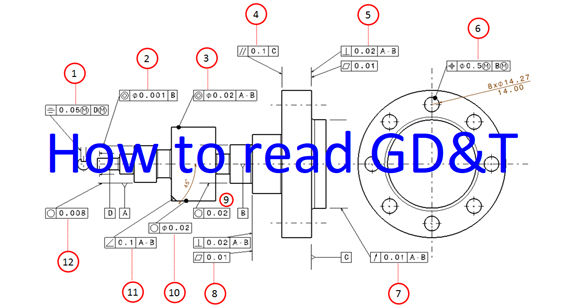

2025 03 17 In the world of precision engineering and CNC machining, achieving accurate part dimensions is essential. Geometric Dimensioning and Tolerancing (GD&T) is a universal engineering language that ensures parts are manufactured correctly and fit together seamlessly. Without a standardized way to define tolerances, inconsistencies can lead to assembly issues, quality control problems, and increased production costs.

66

66

Read more

Read more

VMT

VMT  2025 03 14

2025 03 14 Engineering drawings are the backbone of manufacturing and CNC machining, serving as the universal language between designers, engineers, and machinists. However, poorly executed drawings can lead to miscommunication, machining errors, and increased production costs.

66

66

Read more

Read more

VMT

VMT  2025 03 13

2025 03 13 Have you ever looked at an engineering drawing and felt overwhelmed by the symbols and abbreviations? These intricate diagrams contain essential technical details that guide machinists, engineers, and manufacturers in creating precise CNC machined parts. However, understanding them can be challenging, especially for those unfamiliar with standard engineering drawing conventions.

66

66

Read more

Read more

VMT

VMT  2025 03 12

2025 03 12 Titanium is one of the most valuable and widely used metals in industries such as aerospace, medical, and CNC machining due to its high strength, corrosion resistance, and lightweight properties. However, its price can fluctuate significantly, leaving many manufacturers, buyers, and investors wondering:

66

66

Read more

Read more

VMT

VMT  2025 03 11

2025 03 11 In today's advanced manufacturing industries, achieving high-precision, strong, and reliable welds is essential. Traditional welding methods often lead to excessive heat input, material distortion, and a need for post-processing. These challenges make laser welding a game-changer, offering unmatched speed, accuracy, and efficiency for a wide range of materials.

66

66

Read more

Read more

VMT

VMT  2025 03 10

2025 03 10 Choosing the right type of metal for CNC machining, manufacturing, and industrial applications can be confusing. Should you use ferrous metals or non-ferrous metals? Which is better for strength, corrosion resistance, weight, or cost? If you're unsure about the differences, you're not alone.

66

66

Read more

Read more

VMT

VMT  2025 03 08

2025 03 08 Whether you're looking for custom CNC machining, high-precision components, or mass production solutions, China offers a vast network of manufacturers with competitive pricing and high-quality services. But with so many options available, how do you determine which company is the best fit for your needs?

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!