15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 04 15

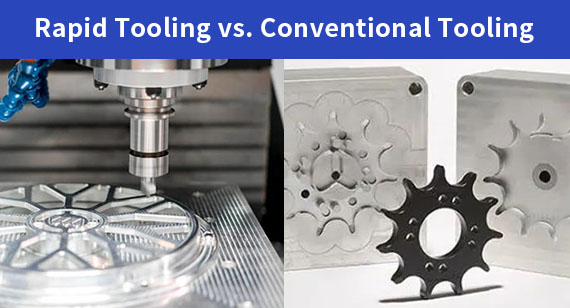

2025 04 15 When selecting the right tooling for your manufacturing project, understanding the differences between rapid tooling and traditional tooling can be the key to saving both time and money. While rapid tooling can offer faster production times and cost savings, traditional tooling is often the go-to choice for high-volume and precise manufacturing. But how do you choose between them? In this comprehensive guide, we’ll walk you through the advantages, disadvantages, and applications of each method, helping you make an informed decision.

66

66

Read more

Read more

VMT

VMT  2025 04 14

2025 04 14 Rapid tooling is a fast and cost-effective method used in manufacturing to produce molds and tools quickly for prototype testing. It reduces the time to market and allows for quick design iterations. Unlike traditional tooling, rapid tooling is ideal for low-volume production and short-run projects, offering a significant advantage in product development.

66

66

Read more

Read more

VMT

VMT  2025 04 11

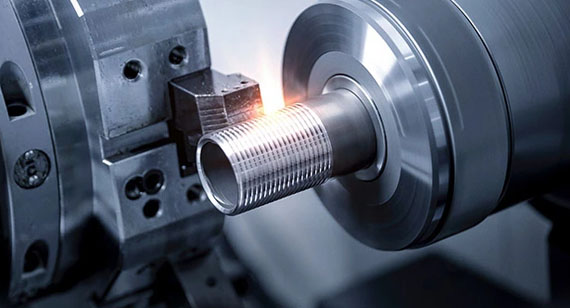

2025 04 11 Thread machining is a precision process used to create helical grooves (threads) on internal or external surfaces of cylindrical parts. It can be performed using taps, dies, CNC milling machines, or turning centers. It plays a vital role in part functionality and assembly and is critical in automotive, aerospace, and electronics industries.

66

66

Read more

Read more

VMT

VMT  2025 04 10

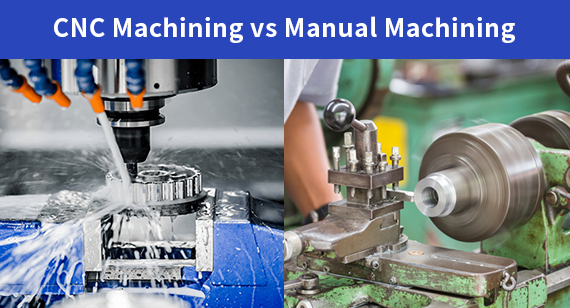

2025 04 10 Struggling to decide between CNC machining and manual machining for your next project? You’re not alone. Many product designers, engineers, and manufacturers face the same challenge—balancing precision, cost, flexibility, and speed. Choosing the wrong method can lead to delays, unnecessary expenses, and compromised quality. Whether you're developing a prototype or planning large-scale production, understanding the core differences and advantages of each approach is key. The good news? There's a clear path forward when you understand how each process works and where it excels.

66

66

Read more

Read more

VMT

VMT  2025 04 09

2025 04 09 There are over 15 types of turning operations, including facing, taper turning, grooving, boring, and threading. Each method supports different shapes, tolerances, and materials. Choosing the correct type depends on your part’s geometry, surface finish requirements, and production volume. CNC turning services can integrate multiple operations to achieve high precision and production efficiency.

66

66

Read more

Read more

VMT

VMT  2025 04 08

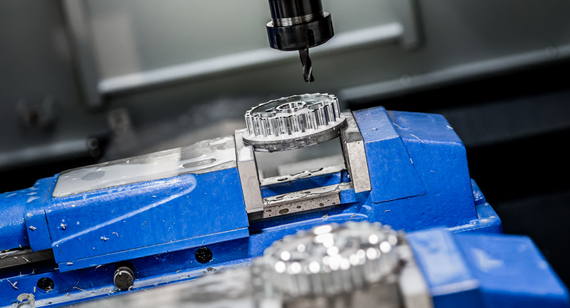

2025 04 08 Milling operations use rotating cutting tools to remove material from a stationary workpiece. There are many types of milling operations—such as face, slot, end, and gear milling—each designed to achieve specific shapes, dimensions, and finishes. CNC milling improves precision and productivity by automating these operations through computer-controlled machines.

66

66

Read more

Read more

VMT

VMT  2025 04 07

2025 04 07 Struggling to decide which machining process is right for your manufacturing project? You’re not alone. With so many machining technologies available—from traditional turning to laser beam machining—the choices can be overwhelming. Without the right understanding, you risk wasting time, money, and resources. But here’s the good news: this guide will simplify the complex world of machining operations and help you identify the best solution for your specific needs.

66

66

Read more

Read more

VMT

VMT  2025 04 06

2025 04 06 When selecting materials for demanding environments, stainless steel is often the go-to choice. But even within the same series—like 316 vs. 316L—making the right decision isn’t always simple. You may struggle to decide which offers better corrosion resistance, weldability, or long-term value. Choosing the wrong type could mean premature failure, higher costs, or poor performance.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!