15 years one-stop China custom CNC machining parts factory

564 |

Published by VMT at Nov 21 2024 | Reading Time:About 6 minutes

564 |

Published by VMT at Nov 21 2024 | Reading Time:About 6 minutes

Are you struggling to find a manufacturing process that combines flexibility, efficiency, and cost-effectiveness for creating complex aluminum parts? Frustrated by limitations in traditional fabrication methods that fail to deliver the precision and versatility your projects demand? You're not alone. Many engineers and manufacturers face challenges in producing intricate aluminum components that meet stringent quality standards without escalating costs. But what if aluminum extrusion could be the game-changing solution you've been searching for—offering unparalleled design freedom and seamless integration with aluminum CNC machining to bring your most ambitious concepts to life?

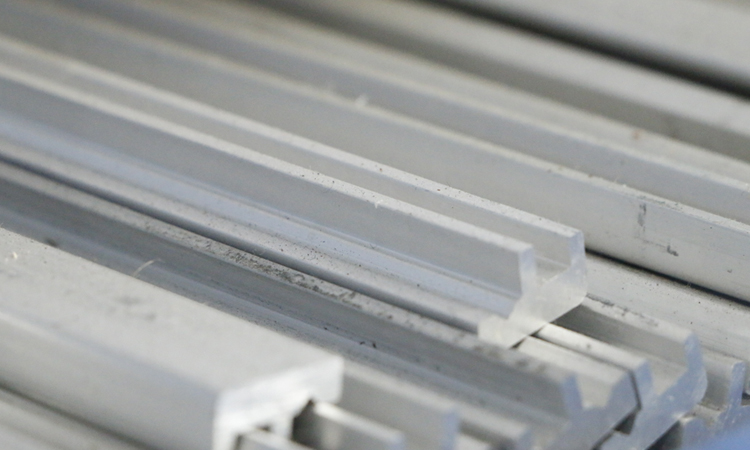

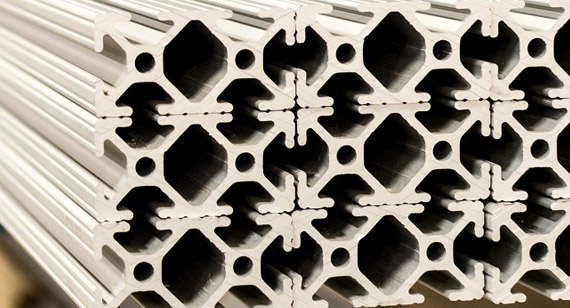

Aluminum extrusion is a manufacturing process where aluminum alloy material is forced through a die with a specific cross-sectional profile, allowing for the creation of complex shapes with excellent structural integrity and surface finish. This process is ideal for producing custom aluminum parts efficiently and cost-effectively, especially when combined with CNC machining services for precision detailing.

Now that we've introduced aluminum extrusion as a transformative solution for your manufacturing challenges, let's delve deeper into what this process entails. Understanding the intricacies of aluminum extrusion will empower you to harness its full potential, whether you're producing standard profiles or intricate custom designs that require the precision of CNC machining parts. Let's explore the various aspects of aluminum extrusion, from the technologies involved to the applications that make it indispensable in today's industries.

Foreword

In the modern manufacturing landscape, the demand for lightweight, durable, and versatile materials is ever-increasing. Aluminum stands out as a material of choice due to its excellent strength-to-weight ratio, corrosion resistance, and recyclability. Among the various methods to shape aluminum, extrusion has emerged as a highly efficient and flexible process. Aluminum extrusion enables the production of complex cross-sectional profiles that are integral to a multitude of industries, including aerospace, automotive, construction, and electronics.

This comprehensive guide aims to provide an in-depth understanding of aluminum extrusion, covering the fundamental concepts, different technologies, the extrusion process step-by-step, factors affecting extrusion, post-processing options, advantages and disadvantages, and practical applications. Whether you're an engineer, designer, or manufacturer, this guide will equip you with the knowledge to make informed decisions and optimize your use of aluminum extrusion in conjunction with custom CNC machining services.

Aluminum extrusion is a metal forming process that transforms aluminum alloy into objects with a definitive cross-sectional profile for a wide range of uses. The process involves forcing a heated aluminum billet through a die of the desired cross-section using a hydraulic or mechanical press. As the aluminum passes through the die, it emerges in the shape of the die opening, much like how toothpaste is squeezed out of a tube.

The versatility of aluminum extrusion allows for the creation of complex and intricate profiles that would be difficult or impossible to achieve through other manufacturing methods. These profiles can range from simple solid shapes like rods and bars to complex hollow profiles with multiple chambers.

Key Characteristics of Aluminum Extrusion:

Design Flexibility: Allows for the creation of custom shapes tailored to specific applications.

Material Efficiency: Minimizes waste by producing profiles close to the final shape, reducing the need for extensive machining.

Structural Integrity: Produces components with excellent mechanical properties and uniform grain structures.

Surface Finish: Results in smooth surfaces that are ideal for further finishing processes like anodizing or painting.

Aluminum extrusion is often combined with aluminum CNC machining to achieve precise dimensions and complex features, enhancing the functionality and aesthetics of the final product. The process is integral to various industries, offering a cost-effective and efficient way to produce high-quality aluminum components.

Aluminum extrusion is not a one-size-fits-all process. Various technologies have been developed to cater to different requirements, materials, and product complexities. Understanding these technologies is crucial for selecting the most suitable method for your specific application. The two primary aluminum extrusion technologies are Direct Aluminum Extrusion and Indirect Aluminum Extrusion.

Direct Aluminum Extrusion

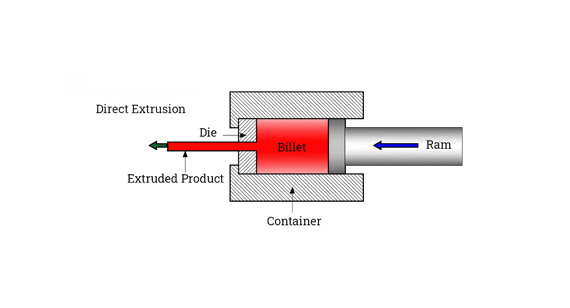

Direct Aluminum Extrusion, also known as forward extrusion, is the most common extrusion method. In this process, the aluminum billet and the ram move in the same direction. The heated billet is placed inside a stationary container, and a hydraulic ram pushes the billet through the die at the other end.

Characteristics of Direct Extrusion:

Versatility: Suitable for a wide range of profiles, including solid, hollow, and semi-hollow shapes.

Force Requirement: Requires higher force due to friction between the billet and the container walls.

Die Wear: Increased friction can lead to more significant die wear, affecting the tool's lifespan.

Advantages:

Flexibility in Shapes: Can produce complex cross-sections.

Ease of Operation: Simpler setup and widely understood process.

Disadvantages:

Higher Energy Consumption: Due to greater force required.

Tooling Wear: Increased friction leads to faster wear of dies and containers.

Indirect Aluminum Extrusion

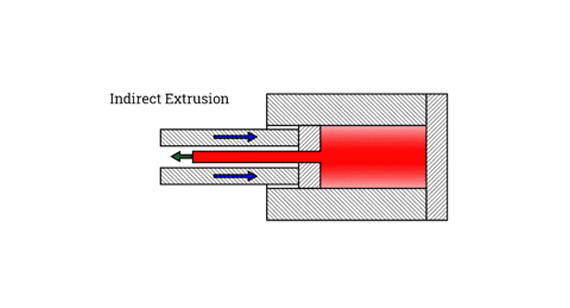

Indirect Aluminum Extrusion, or backward extrusion, involves the die being pushed against the stationary billet. In this method, the container moves while the billet remains stationary. The die is mounted on the ram, and as it moves, the aluminum flows through the die in the opposite direction of the ram movement.

Characteristics of Indirect Extrusion:

Reduced Friction: Since there's no relative movement between the billet and container walls.

Lower Force Requirement: Less force is needed compared to direct extrusion.

Improved Surface Finish: Reduced friction leads to better surface quality.

Advantages:

Energy Efficiency: Lower energy consumption due to reduced friction.

Longer Tool Life: Less wear on dies and containers.

Better Mechanical Properties: More uniform material flow results in consistent grain structure.

Disadvantages:

Limited Shapes: Not as versatile in producing complex profiles.

Equipment Complexity: Requires specialized equipment, making it less common.

One of the most significant advantages of aluminum extrusion is the ability to create a wide variety of shapes to meet specific design requirements. The main categories of extrusion shapes include solid shapes, hollow shapes, semi-hollow shapes, and custom aluminum extrusion shapes. Each category serves different functional and aesthetic purposes in various applications.

Solid Shapes

Solid Shapes are profiles without any enclosed voids or openings. Examples include:

Applications:

Hollow Shapes

Hollow Shapes contain one or more voids or openings in the cross-section. These are created using special dies with pins or mandrels to form the hollow areas.

Examples:

Applications:

Semi-Hollow Shapes

Semi-Hollow Shapes are profiles where the voids are not entirely enclosed, typically featuring a partially enclosed void.

Examples:

Applications:

Custom Aluminum Extrusion Shapes

Custom Aluminum Extrusion Shapes are tailored to specific design requirements that standard profiles cannot meet. Utilizing the flexibility of extrusion, manufacturers can create intricate and unique cross-sections.

Advantages:

Applications:

By leveraging custom CNC machining in conjunction with aluminum extrusion, manufacturers can achieve even greater precision and complexity in their custom profiles. This combination is particularly beneficial for producing intricate features and tight tolerances that extrusion alone cannot provide.

Understanding the aluminum extrusion process step-by-step provides valuable insights into how raw aluminum is transformed into functional and aesthetically pleasing components. The process involves several critical stages, each contributing to the quality and characteristics of the final product. Here's a detailed walkthrough of the aluminum extrusion process:

Step 1: Prepare the Extrusion Die

The extrusion process begins with the design and preparation of the extrusion die:

Step 2: Preheat the Aluminum Billet

An aluminum billet is a cylindrical piece of aluminum alloy that serves as the raw material:

Step 3: Move the Billet to the Extruder

Once preheated:

Step 4: Press the Extruded Material Against the Die

The extrusion process begins in earnest:

Step 5: Quench the Extrusion

As the extrusion exits the die:

Step 6: Shear the Extrusion to Table Length

The continuous extrusion is:

Step 7: Cool the Extrusion to Room Temperature

Further cooling is necessary:

Step 8: Transfer the Extrusion to a Stretcher and Stretch It to Alignment

To correct any distortions:

Step 9: Transfer the Extrusion to a Finishing Saw and Cut It to Desired Lengths

The extrusions are then:

Step 10: Perform Secondary Operations (Heat Treating, Fabricating, and Surface Treatments)

To achieve final specifications:

By following these steps meticulously, manufacturers ensure that the extruded aluminum profiles meet stringent quality standards and are ready for their intended applications.

Several factors influence the aluminum extrusion process, affecting the quality, mechanical properties, and dimensional accuracy of the final product. Understanding and controlling these factors is essential for optimizing the extrusion process and achieving consistent results. Key factors include:

1. Extrusion Speed

Extrusion Speed refers to the rate at which the aluminum billet is pushed through the die:

2. Extrusion Ratio

Extrusion Ratio is the ratio of the billet's cross-sectional area to that of the extruded profile:

3. Billet Temperature

Billet Temperature is critical for material flow:

4. Extruder

Extruder Characteristics play a significant role:

5. Extrusion Shape

Profile Complexity affects the process:

These Parameters Also Need to Be Carefully Monitored:

Product Dimensions and Tolerances

Macrostructure of Bars/Tubes/Profiles

Surface Treatment

Mechanical Properties

Other Special Quality Considerations

By carefully monitoring and controlling these factors, manufacturers can optimize the extrusion process to produce high-quality aluminum profiles suitable for further processing, including CNC prototype machining and finishing services.

Post-processing enhances the functionality, aesthetics, and performance of extruded aluminum parts. These processes include heat treatments, machining, and various surface treatments, all of which can be tailored to meet specific application requirements.

Metal Heat Treatment Processes

Heat Treatment alters the mechanical properties of aluminum:

Benefits:

Machining Operations refine extrusions:

Advantages:

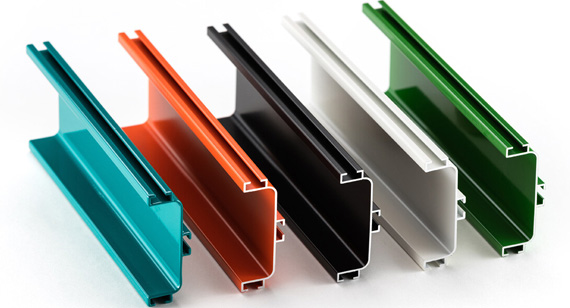

Surface treatments protect and enhance the appearance of aluminum extrusions. They improve corrosion resistance, wear resistance, and aesthetics. Common surface treatments include:

Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on the aluminum surface:

Benefits:

Applications: Used in architectural components, consumer electronics, and automotive parts.

Painting

Painting applies a liquid coating to the aluminum surface:

Benefits:

Applications: Suitable for visible components where aesthetics are important.

Powder Coating

Powder Coating involves electrostatically applying a dry powder, followed by curing:

Benefits:

Applications: Used in outdoor furniture, automotive parts, and appliances.

Sandblasting

Sandblasting cleans and textures the surface:

Benefits:

Applications: Used in components requiring a specific surface texture.

Silk Screen Printing

Silk Screen Printing applies graphics or text:

Benefits:

Applications: Common in control panels, electronic devices, and signage.

Laser Engraving

Laser Engraving uses a laser to etch designs:

Benefits:

Applications: Ideal for serial numbers, barcodes, and decorative elements.

By selecting appropriate post-processing options, manufacturers can enhance the performance and appearance of extruded aluminum parts, making them suitable for a wide range of applications.

Aluminum extrusion offers numerous benefits, but it's essential to consider both the advantages and limitations to determine if it's the right manufacturing method for your project.

Advantages

Extruded Aluminum Is Generally Harder and Stronger

Enhanced Mechanical Properties: The extrusion process aligns the grain structure, improving strength and hardness.

Low Industrial Cost

High Operational Flexibility

Economical for Processing Complex Cross-Sections

Perfect Surface Finish and Strength

Disadvantages

Limited by the Capacity of the Steel Container on the Extruder

Die Wear and Maintenance

Extruded aluminum parts are integral to various industries due to their versatility, strength, and lightweight nature. Here are some key sectors where aluminum extrusion plays a vital role:

Aerospace

Food Industry

At VMT, we specialize in providing custom CNC machining services for extruded aluminum parts, even in small batches. Our capabilities include:

Our expertise allows us to cater to diverse industries, delivering high-quality, custom solutions that meet your specific needs.

Aluminum extrusion is a versatile and efficient manufacturing process that enables the production of complex, high-quality aluminum profiles suitable for a wide array of applications. By understanding the nuances of the extrusion process, including the technologies involved, factors affecting extrusion, and post-processing options, manufacturers and designers can make informed decisions to optimize their products.

Combining aluminum extrusion with CNC machining services enhances the possibilities, allowing for intricate details and precise dimensions that meet the most demanding specifications. Whether you're producing large structural components or intricate custom parts, aluminum extrusion offers a cost-effective and flexible solution.

By leveraging the advantages of aluminum extrusion and addressing its limitations through careful planning and advanced technologies, you can achieve superior results that elevate your products and satisfy your customers' needs.

Which Aluminum Alloys Are Suitable for Extrusion?

Common aluminum alloys suitable for extrusion include the 6xxx series (such as 6061 and 6063) and the 7xxx series (such as 7005). The 6xxx series is widely used due to its excellent extrudability, good mechanical properties, and corrosion resistance. The choice of alloy depends on the required mechanical properties, corrosion resistance, and finishing requirements.

What Are the Factors That Affect the Cost of Aluminum Extrusion?

Several factors influence the cost of aluminum extrusion:

Which Is Better for Extrusion, 6061 Aluminum or 7075 Aluminum?

What Is the Difference Between Extruded Aluminum and Forged Aluminum?

What Are the Most Common Aluminum Extrusions?

Common aluminum extrusions include:

What Is the Difference Between Aluminum and Extruded Aluminum?

What Is 6061 Extrusion?

6061 Extrusion refers to aluminum profiles extruded from 6061 alloy. This alloy is popular due to its good mechanical properties, weldability, and corrosion resistance. It's used in structural components, automotive parts, and recreational equipment.

What Is the Difference Between Extruded Aluminum and Anodized Aluminum?

Extruded Aluminum: Aluminum shaped through the extrusion process, resulting in specific profiles.

Anodized Aluminum: Extruded aluminum that has undergone anodizing, an electrochemical process that enhances corrosion resistance and allows for coloring.

By comprehensively understanding aluminum extrusion and its integration with CNC machining services, you can optimize your manufacturing processes, reduce costs, and produce high-quality aluminum components that meet the demands of today's competitive markets.