15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 05 08

2025 05 08 PBT, ABS, POM, and aluminum are the most common mechanical keyboard keycap materials. PBT offers durability and texture, ABS provides smoothness and affordability, POM features a soft feel with RGB compatibility, and aluminum brings premium aesthetics and longevity. Each has unique pros and cons—choose based on typing comfort, design preferences, and performance needs.

66

66

Read more

Read more

VMT

VMT  2025 05 07

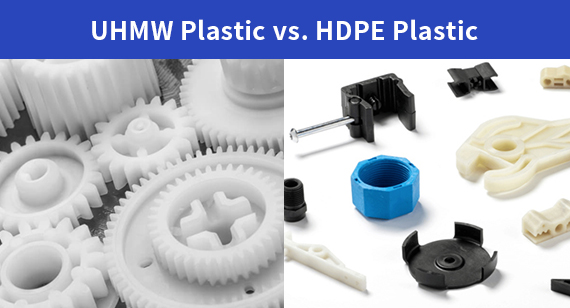

2025 05 07 UHMW is better suited for high-wear, industrial applications due to its superior abrasion resistance and durability, while HDPE is easier to machine, more cost-effective, and ideal for low-stress parts. Choosing between them depends on application demands, required strength, wear resistance, and budget.

66

66

Read more

Read more

VMT

VMT  2025 05 06

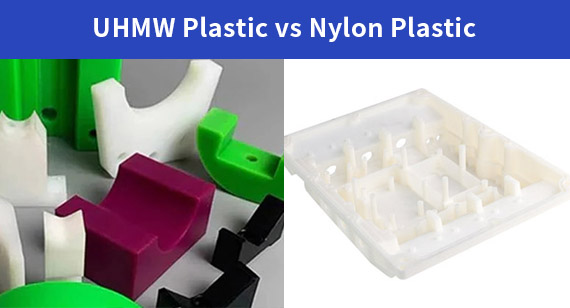

2025 05 06 When comparing UHMW and Nylon, both materials have their unique benefits. UHMW is preferred for high-wear environments due to its abrasion resistance, while Nylon excels in applications requiring strength and rigidity. Understanding the differences between these materials will help you make the right decision for your CNC machining needs.

66

66

Read more

Read more

VMT

VMT  2025 05 05

2025 05 05 HDPE and Delrin are two of the most popular materials used in CNC machining. While both offer high performance and versatility, their differences in mechanical strength, chemical resistance, and processability make them suitable for different applications. By understanding the unique characteristics of HDPE and Delrin, you can choose the right material for your next project.

66

66

Read more

Read more

VMT

VMT  2025 04 30

2025 04 30 Delrin vs. UHMW: Delrin offers superior stiffness, dimensional stability, and precision, making it ideal for high-tolerance plastic CNC machined parts. UHMW, on the other hand, excels in abrasion resistance and low friction, making it perfect for wear-heavy applications. Your choice depends on whether you prioritize machinability and rigidity (Delrin) or durability and impact resistance (UHMW).

66

66

Read more

Read more

VMT

VMT  2025 04 29

2025 04 29 Delrin (POM-H), a type of polyoxymethylene (POM), is highly valued for its excellent mechanical properties, low friction, and resistance to wear and chemicals. It's widely used for precision parts in industries like automotive, medical, and electronics. CNC machining offers precision, reliability, and versatility when working with Delrin to produce custom parts.

66

66

Read more

Read more

VMT

VMT  2025 04 28

2025 04 28 Metal stamping is a manufacturing process where flat metal sheets are fed into a stamping press and formed into specific shapes using dies and pressure. It is widely used for producing high-volume, high-precision parts quickly and cost-effectively.

66

66

Read more

Read more

VMT

VMT  2025 04 25

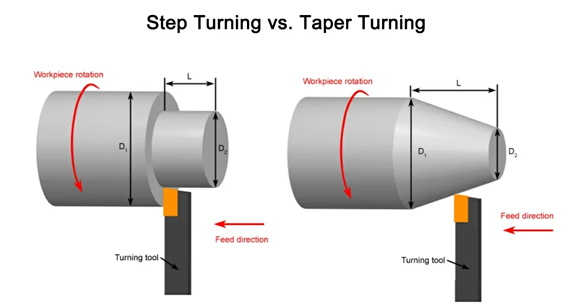

2025 04 25 Step turning involves machining a series of cylindrical steps with varying diameters, while taper turning creates a smooth, angled profile between a larger and smaller diameter. The choice depends on your design requirements—step turning for uniform shoulders, taper turning for conical transitions.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!