15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 05 19

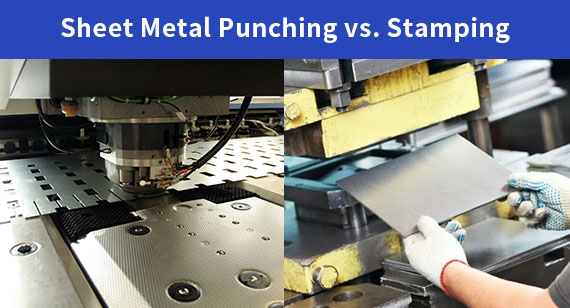

2025 05 19 Sheet metal punching and stamping differ in process, tooling, and application: punching uses a press to shear holes or shapes in flat metal, while stamping shapes or forms the material using dies. Punching is ideal for simpler, high-speed jobs, while stamping is better for detailed, high-volume parts. Choose based on complexity, volume, and cost.

66

66

Read more

Read more

VMT

VMT  2025 05 17

2025 05 17 Metal fabrication is the process of designing, cutting, shaping, assembling, and finishing metal to create durable, functional components for a wide range of industries. It involves various methods—like welding, CNC machining, and forming—and is used to produce everything from structural beams to precision medical parts. This guide covers all key steps, technologies, materials, and applications involved.

66

66

Read more

Read more

VMT

VMT  2025 05 16

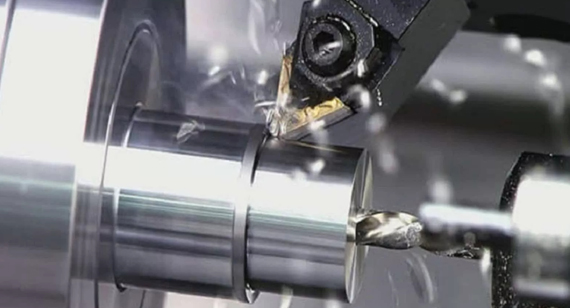

2025 05 16 Step turning is a lathe machining process used to create multiple diameters or "steps" along the length of a cylindrical workpiece. It involves turning the part in stages, typically using a CNC lathe, and is ideal for producing shafts and mechanical components with varying cross-sections. This process improves efficiency, accuracy, and part uniformity in CNC turning operations.

66

66

Read more

Read more

VMT

VMT  2025 05 15

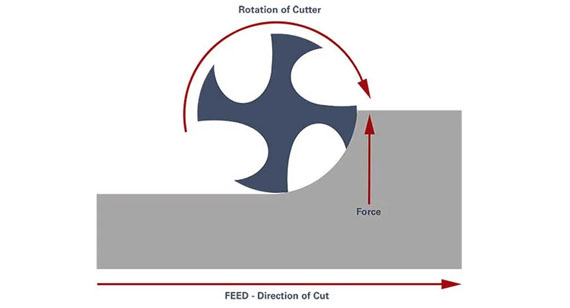

2025 05 15 Down milling, also known as climb milling, involves the cutter rotating in the same direction as the feed, resulting in a smoother finish and reduced tool wear. Conversely, reverse milling, or conventional milling, has the cutter rotating against the feed direction, offering better control on harder materials but potentially leading to increased tool wear and surface imperfections. The choice between these methods depends on material properties, desired surface finish, and machine capabilities.

66

66

Read more

Read more

VMT

VMT  2025 05 14

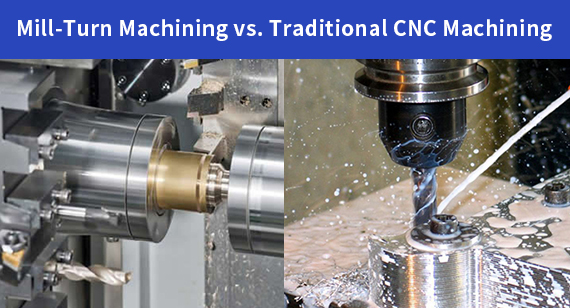

2025 05 14 Mill-Turn machining integrates milling and turning operations into a single setup, enhancing efficiency for complex parts. Traditional CNC machining, involving separate milling and turning processes, is often more cost-effective for simpler components. The optimal choice depends on part complexity, production volume, and precision requirements.

66

66

Read more

Read more

VMT

VMT  2025 05 13

2025 05 13 The main difference between CNC Swiss machining and traditional CNC machining lies in how the material is supported and moved: Swiss machines move the bar stock through a sliding headstock, improving stability for small, high-precision parts, while traditional CNC machines keep the workpiece stationary. Swiss machining is ideal for complex, long, small-diameter components requiring tight tolerances.

66

66

Read more

Read more

VMT

VMT  2025 05 12

2025 05 12 304 and 316 stainless steels are widely used in CNC machining, but understanding the differences between 304, 304L, 316, and 316L grades can help you select the best material for your needs. The major differences lie in their chemical composition, corrosion resistance, and weldability, with 316L offering superior corrosion resistance in marine and high-saline environments.

66

66

Read more

Read more

VMT

VMT  2025 05 09

2025 05 09 The main difference between 316, 304, and 308 stainless steel lies in their chemical composition and corrosion resistance. 316 contains molybdenum for superior chloride resistance, 304 is the most versatile and cost-effective, while 308 is optimized for welding 304 components. Choosing the right grade depends on your application’s environment, mechanical needs, and weldability requirements.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!