15 years one-stop China custom CNC machining parts factory

501 |

Published by VMT at Dec 15 2024 | Reading Time:About 3 minutes

501 |

Published by VMT at Dec 15 2024 | Reading Time:About 3 minutes

Are you struggling to find a material that combines strength, dimensional stability, and heat resistance for your precision machined parts? Perhaps you’ve tried standard plastics only to be disappointed by their limited rigidity or susceptibility to creep under load. These issues can lead to premature wear, poor performance, and costly redesigns. In competitive industries, subpar materials can compromise product quality, customer satisfaction, and even your reputation as a reliable supplier.

Without a suitable solution, you risk dealing with parts that warp under heat, degrade when exposed to aggressive chemicals, or fail to hold tight tolerances. This leads to unpredictable performance and higher maintenance costs, draining resources and eroding profit margins. The frustration of repeatedly attempting to fine-tune materials and processes—only to end up back at square one—is enough to cause serious headaches in any CNC machining factory.

Enter glass-filled nylon—an advanced engineering plastic reinforced with glass fibers that significantly enhance its mechanical and thermal properties. By integrating glass-filled nylon into your custom CNC machining projects, you can produce precision machined parts that withstand high loads, maintain dimensional stability, and offer improved impact resistance. As you read on, you’ll discover everything from the types, advantages, and disadvantages of glass-filled nylon to practical guidance on selecting the right grade for your CNC prototype machining endeavors. This knowledge will empower you to leverage CNC machining services to deliver durable, reliable, and high-performance parts that keep you ahead in the market.

For stronger, more dimensionally stable machined components, choose glass-filled nylon. Its glass fiber reinforcement enhances strength, heat resistance, and rigidity, making it ideal for precision machined parts. Consult a CNC machining shop to select the right grade, ensure proper tooling, and achieve consistent quality. This solution reduces creep, improves load-bearing capacity, and prolongs part life.

Now that you know how glass-filled nylon can address performance shortfalls in standard plastics, let’s explore this material in greater depth. From understanding its basic composition and properties to comparing it against similar materials, we’ll guide you through every aspect. By the end, you’ll be equipped to choose the right glass-filled nylon grade, employ effective processing methods, and confidently integrate it into your CNC machining services.

Foreword

Glass-filled nylon isn’t just another plastic—it’s a game-changer that bridges the gap between metal and polymeric materials. Whether you’re producing automotive components, industrial gears, or electronics housings, this composite material’s unique balance of strength, stiffness, and thermal stability makes it invaluable. For CNC machining services seeking to offer robust solutions, mastering glass-filled nylon is essential. In the sections that follow, we’ll detail the composition, mechanical properties, advantages, drawbacks, and practical applications of glass-filled nylon, empowering you to make informed decisions.

Glass-filled nylon is a thermoplastic composed of a nylon resin matrix—often Nylon 6, Nylon 6/6, or PA12—reinforced with short strands of glass fibers. These fibers, typically 10% to 50% by weight, enhance the polymer’s mechanical properties. The result is a composite material offering improved tensile strength, stiffness, heat deflection temperature, and dimensional stability compared to unfilled nylon. This makes it ideal for precision machined parts that must withstand higher loads, maintain tight tolerances, and resist environmental challenges. By leveraging custom CNC machining with glass-filled nylon, manufacturers can produce plastic parts machining outcomes that rival metal components in demanding applications.

Glass-filled nylon can be substantially stronger than its unfilled counterpart. While unfilled nylons are already well-regarded for their toughness and resilience, adding glass fibers amplifies their load-bearing capacity and stiffness. Tensile strength and modulus can increase significantly, enabling the resulting parts to handle mechanical stress, vibration, and shock with greater resilience. Moreover, glass-filled nylon’s improved dimensional stability ensures that components maintain their shape under temperature fluctuations and mechanical loads. This means parts like gears, brackets, and housings can operate reliably even in challenging operating conditions, making glass-filled nylon CNC machined parts a top choice for industries requiring robust performance.

Nylon 12 (PA12) is a versatile, low-moisture absorbing nylon known for its chemical resistance and stability. It’s often chosen for parts requiring good flexibility and dimensional accuracy but less extreme mechanical demands. Glass-filled nylon, on the other hand, incorporates glass fibers to bolster strength and stiffness far beyond what PA12 alone can provide. While PA12 excels in applications needing ductility and chemical resistance, glass-filled variants deliver improved rigidity, reduced creep, and better load support. Selecting between them depends on your project’s priorities—if maximum strength and reduced deformation are top concerns, glass-filled nylon outshines even a stable, well-regarded nylon like PA12.

Yes, glass-filled nylon is very strong relative to standard thermoplastics. The incorporation of glass fibers creates a composite that can rival metals in certain applications, especially where weight reduction is critical. This strength isn’t merely about static loads; it also improves impact resistance, reducing the risk of cracks or deformation under sudden shocks. For precision machined parts that must endure heavy-duty conditions—such as industrial machinery components, automotive engine bay parts, or load-bearing structural components—glass-filled nylon’s strength and rigidity enable consistent performance throughout the part’s lifespan.

While glass-filled nylon offers remarkable benefits, it’s not without trade-offs. Understanding both sides of the equation ensures that you choose this material wisely for your CNC machining services.

Advantages of Glass-Filled Nylon

The following advantages highlight why many CNC machining factories and product designers turn to glass-filled nylon:

Disadvantages of Glass-Filled Nylon

Despite its many benefits, glass-filled nylon also presents some drawbacks:

Various formulations exist, each tuned to specific performance criteria. Choosing the right grade ensures that your plastic parts machining project aligns with application demands:

Production methods vary based on part complexity, volume, and performance requirements. Common approaches:

3D Printing:

Ideal for prototypes or complex geometries. Glass-filled nylon filaments or powders can produce strong, lightweight components.

Injection Molding:

Perfect for high-volume production of intricate shapes. Glass-filled nylon pellets are melted and injected into molds for quick, repeatable results.

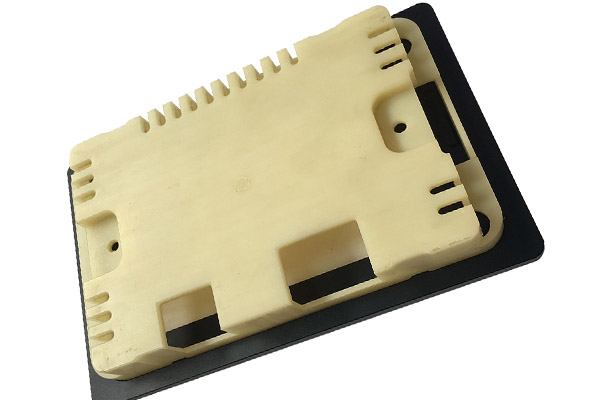

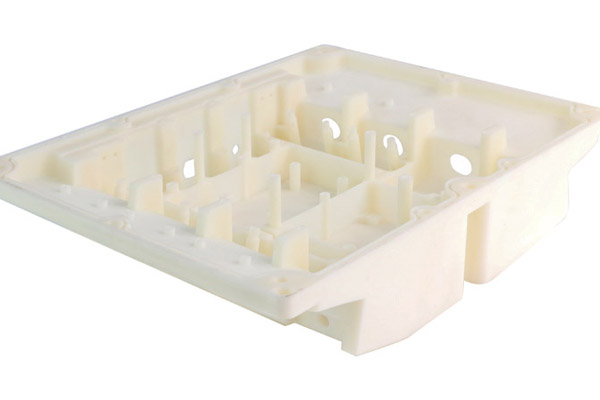

For custom CNC machining, starting from blocks or rods of glass-filled nylon allows for precise milling, turning, and drilling. CNC machining factory services produce tight-tolerance features essential in demanding assemblies.

When you combine CNC machining with 3D-printed blanks of glass-filled nylon, you gain:

Enhancing 3D printed components with glass-filled nylon yields improved mechanical properties, better dimensional consistency, and the ability to refine complex shapes post-print. This synergy allows rapid prototyping without sacrificing the ruggedness needed for functional testing. For CNC prototype machining, starting with 3D-printed near-net shapes and finishing them via CNC machining services shortens lead times and reduces material waste.

Different grades of PA12 and other nylons vary in properties such as tensile strength, modulus, and heat deflection temperature.

PA 12 Mineral Filled (PA620-MF)

PA 12 40% Glass Filled (PA614-GS)

PA 12 40% Glass Filled Black

| Material |

PA 12 Mineral-Filled (PA620-MF) |

PA 12 40% Glass-Filled (PA 614-GS) |

PA 12 40% Glass-Filled Black |

| Process |

SLS |

SLS |

MJF |

| Color |

Light Gray |

White |

Black |

| Tensile Strength |

5.51 ksi (38.0MPa) |

7.25 ksi (50.0MPa) |

4.35 ksi (30.0MPa) |

| Tensile Modulus |

450 ksi (3,100MPa) |

522 ksi (3,600MPa) |

508 ksi (3,500MPa) |

| Elongation |

3% |

5% |

8.5% |

| Heat Deflection Temp. @ 0.46 MPa |

363° F 184° C |

314° F 157° C |

347° F 175° C |

| Heat Deflection Temp. @ 1.82 MPa |

354° F 179° C |

204° F 96° C |

248° F 120° C |

Injection molding glass-filled nylon yields strong, dimensionally stable components with faster production rates and uniform properties. This synergy suits automotive brackets, industrial gears, electronic housings, and more. High volume moldings achieve cost-effectiveness and repeatability unmatched by many other engineering plastics. The result: mass-produced parts that retain mechanical integrity and consistent quality.

While beneficial, glass-filled nylon poses processing challenges that must be addressed:

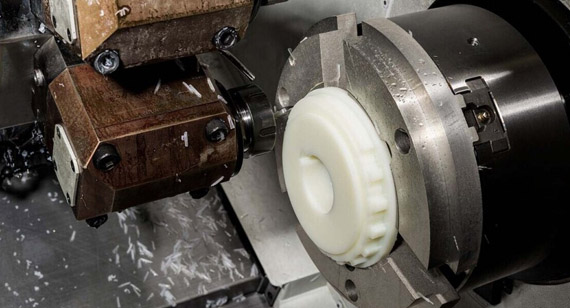

Excessive Tool Wear:

Glass fibers act as abrasives, wearing down cutting edges and molds. Using harder tooling materials (carbide or diamond-coated) and optimizing cutting parameters mitigates wear.

Delamination:

Anisotropy and shrinkage can lead to layering or poor bonding between layers. Controlling mold conditions, drying materials properly, and using optimal injection speeds reduce these defects.

Glass-filled nylon’s robust properties open doors across multiple sectors:

Industry Applications:

Industry Part Applications

Beyond traditional machining and molding, evolving technologies enable new approaches:

Some Alternative Methods for Processing PA+GF:

Combining these methods with CNC machining (for final finishing) enhances precision and finishes, optimizing part performance and appearance.

For manufacturers and engineers seeking reliable suppliers, working with a CNC machining factory like VMT ensures access to CNC machining services specializing in glass-filled nylon CNC machined parts. Expertise in material selection, tool management, and process optimization results in superior plastic parts machining outcomes that align with project specifications.

Glass-filled nylon emerges as a versatile, high-performance solution for precision machined parts across many industries. Its reinforced structure enhances strength, stiffness, heat resistance, and dimensional stability, making it a top choice for custom CNC machining. While it presents challenges—like increased tool wear and higher costs—appropriate material selection, tooling strategies, and processing methods mitigate these drawbacks. By understanding the types, advantages, disadvantages, and applications of glass-filled nylon, you can confidently choose this advanced engineering plastic for your next CNC machining project.

How to Select the Right Glass-Filled Nylon Grade for Machining Applications?

Consider factors like required mechanical strength, thermal environment, chemical exposure, and dimensional tolerances. Consult data sheets and experts at a CNC machining shop to identify the grade (Nylon 6, Nylon 6/6, PA12, etc.) and glass content that best fits your needs.

What Safety Precautions Are Important When Processing Glass-Filled Nylon?

Wear PPE (safety glasses, gloves) due to glass fiber dust and ensure proper ventilation. Use sharp, wear-resistant tools. Handle granules and dust carefully to avoid inhalation hazards.

How Does Glass-Filled Nylon Compare to Unfilled Nylon?

Glass-filled nylon offers higher strength, stiffness, and heat resistance but at increased cost and potential brittleness. Unfilled nylon is more ductile, lighter, and cheaper but less capable under high loads.

Is Glass-Filled Nylon Stronger Than Polymers?

Compared to most unfilled plastics, yes. Glass-filled nylon often provides mechanical properties approaching lightweight metals, making it suitable for structural or load-bearing roles.

What Is the Difference Between Glass-Filled Nylon and G10?

G10 is a fiberglass laminate (resin-impregnated glass cloth) with high stiffness and electrical insulation. Glass-filled nylon is a thermoplastic composite—easier to process but generally less stiff and stable than G10 in extreme conditions.

What Is the Difference Between Nylon 12 and Glass-Filled?

Nylon 12 offers low moisture absorption and good stability, but less strength and stiffness than glass-filled variants. Glass-filled grades significantly enhance load-bearing capacity and dimensional stability at the expense of ductility and cost.

Is Nylon Better Than Acrylic?

It depends on the application. Nylon is tougher, more impact-resistant, and better for mechanical parts. Acrylic offers clarity and aesthetics. For mechanical strength and performance, nylon (especially glass-filled) often surpasses acrylic.

What is the difference between PA6 and PA66?

PA6 typically has slightly better toughness and lower melting point, while PA66 offers higher strength and a higher melting point. Both can be glass-filled, adjusting their mechanical profiles.

What is the strongest type of nylon?

Glass-filled grades generally provide the highest strength and stiffness. Among these, formulations like PA 6/6 GF or PA12 GF are known for robust mechanical performance under demanding conditions.