15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 12 13

2024 12 13 Are you struggling with subpar off-the-shelf enclosures that never quite fit your product’s specifications, leading to poor protection, substandard aesthetics, or inadequate heat dissipation? Relying on generic housings often results in compromise

66

66

Read more

Read more

VMT

VMT  2024 12 12

2024 12 12 Electroplating is a surface treatment that uses electrical current to deposit a thin metal layer onto a part, improving corrosion resistance, hardness, conductivity, and aesthetics. This process enhances electroplated CNC machining parts, offering a cost-effective solution for industries requiring high-quality finishes, durability, and precise custom CNC machining results.

66

66

Read more

Read more

VMT

VMT  2024 12 11

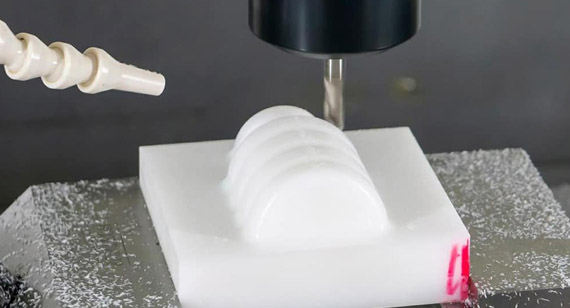

2024 12 11 Enter Teflon, also known as PTFE, a remarkable fluoropolymer that solves many of these headaches. Machining Teflon/PTFE provides a gateway to creating plastic CNC machining parts that excel in high-temperature environments, resist aggressive chemicals, and minimize frictional losses. With Teflon CNC machining parts, you can achieve tight tolerances more consistently than with other fluoropolymers, handle extreme operating conditions from -260°C to 260°C, and maintain dimensional stability over a long service life. By mastering the art of machining Teflon/PTFE, your CNC machining factory can produce reliable, custom CNC machining components that stand up to challenging applications in automotive, medical, aerospace, and beyond. Combined with modern CNC prototype machining techniques and a controlled production environment, PTFE machining grants you the flexibility to meet complex design requirements, reduce waste, and deliver results that impress even the most demanding clients.

66

66

Read more

Read more

VMT

VMT  2024 12 10

2024 12 10 Brass CNC machining is an excellent choice for producing custom brass parts due to its high machinability, strength, and corrosion resistance. Understanding the unique characteristics of brass, selecting the right alloy, and applying the correct machining techniques will ensure high-quality, durable results for your projects. This guide provides everything you need to know about brass machining, from types and finishes to machining tips.

66

66

Read more

Read more

VMT

VMT  2024 12 09

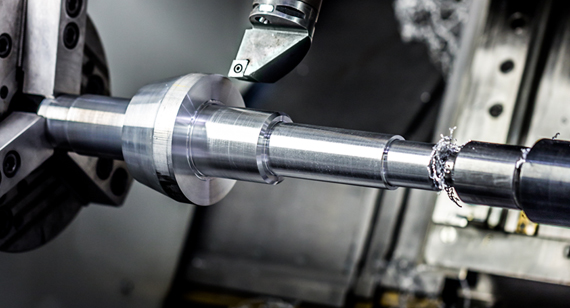

2024 12 09 Understanding the details of custom shaft machining requires diving deeper into the types of shafts, the processes involved, and how different materials impact the final product. Now, let’s explore the steps and technologies that go into designing and manufacturing custom shafts, ensuring they are of the highest quality and suitable for their intended use.

66

66

Read more

Read more

VMT

VMT  2024 12 08

2024 12 08 Undercutting in CNC machining refers to creating features that cannot be reached directly by a tool along a standard path. This includes deep grooves, slots, and channels that are typically inaccessible using conventional cutting tools. CNC machined parts with undercuts require specialized tools and techniques to ensure precision and functionality, making them critical in industries like aerospace, automotive, and medical devices. Mastering the process can significantly enhance the performance of your parts and streamline manufacturing operations.

66

66

Read more

Read more

VMT

VMT  2024 12 07

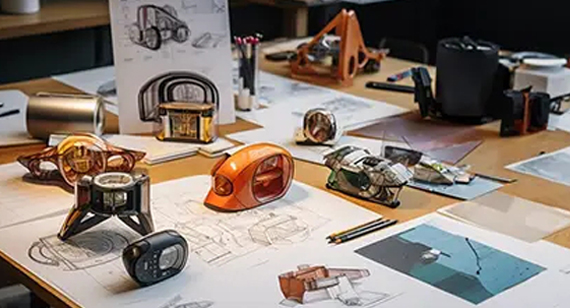

2024 12 07 Industrial Design Prototyping involves creating tangible models of product designs to evaluate functionality, aesthetics, and feasibility before mass production. Utilizing methods such as CNC machining, 3D printing, and vacuum casting, this process streamlines design validation, reduces production costs, and ensures that prototypes accurately reflect the final product's quality and performance standards.

66

66

Read more

Read more

VMT

VMT  2024 12 06

2024 12 06 Product prototype development involves transforming your initial design ideas into physical representations, allowing you to test and refine functionality before full-scale production. From 3D printing to CNC machining services, selecting the right prototyping method is essential for meeting your project’s requirements. The process typically includes researching concepts, detailed design, testing, and preparing for manufacturing. Understanding these steps ensures you can validate your product, avoid costly errors, and ultimately create a functional, market-ready design.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!