15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 11 19

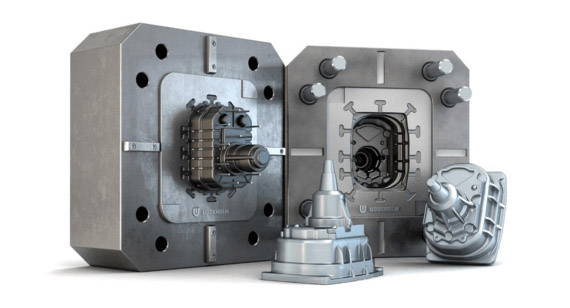

2024 11 19 Die casting is a metal casting process that forces molten metal under high pressure into a mold cavity, allowing for the mass production of complex, high-precision metal parts with excellent surface finishes and dimensional accuracy. It's widely used in industries requiring large quantities of small to medium-sized parts with fine details.

66

66

Read more

Read more

VMT

VMT  2024 11 18

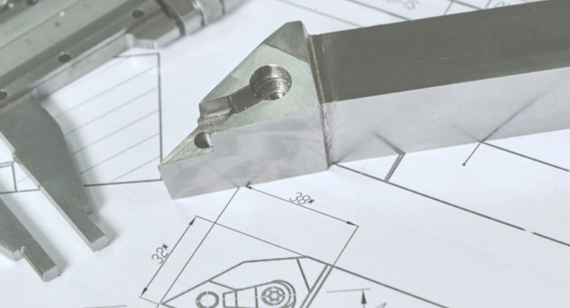

2024 11 18 Are you facing challenges with your CNC machined parts not meeting the exact specifications required for your projects? Frustrated by inconsistencies that lead to costly delays and reworks in your custom CNC machining operations? You're not alone. M

66

66

Read more

Read more

VMT

VMT  2024 11 17

2024 11 17 Tolerance and allowance are fundamental concepts in engineering manufacturing that define the permissible limits of variation in dimensions and the intentional differences between mating parts. Recognizing the difference between tolerance and allowance is essential for precise CNC machined parts, enhancing the efficiency of custom CNC machining, and ensuring the success of your CNC machining services.

66

66

Read more

Read more

VMT

VMT  2024 11 16

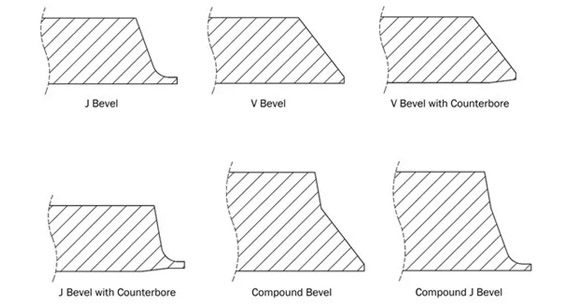

2024 11 16 A bevel is an angled edge or surface that is not perpendicular to the faces of a piece, commonly used in engineering and manufacturing to improve assembly, safety, and aesthetics. Incorporating bevels into CNC machined parts enhances functionality, reduces stress concentrations, and facilitates easier assembly in custom CNC machining processes.

66

66

Read more

Read more

VMT

VMT  2024 11 15

2024 11 15 Engineering plastics are high-performance materials that offer superior mechanical and thermal properties compared to commodity plastics. They are designed for applications requiring enhanced durability, heat resistance, and structural integrity, making them ideal for plastic CNC machining parts in custom CNC machining and CNC prototype machining services.

66

66

Read more

Read more

VMT

VMT  2024 11 14

2024 11 14 Laser etching is a non-contact, versatile method that uses concentrated laser beams to create precise, permanent markings on various materials, including aluminum. It offers unmatched accuracy, speed, and durability, making it an ideal choice for marking aluminum CNC machining parts in custom CNC machining and CNC prototype machining services.

66

66

Read more

Read more

VMT

VMT  2024 11 13

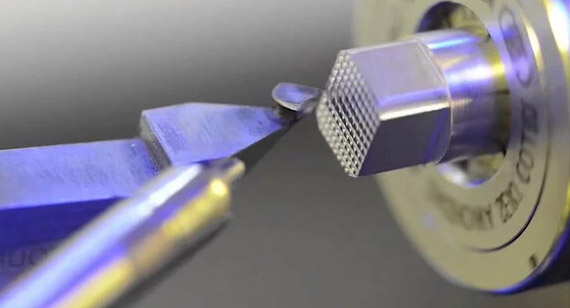

2024 11 13 Diamond machining utilizes diamond-tipped tools to achieve exceptional surface finishes and ultra-precise dimensions in CNC machined parts. By leveraging the unparalleled hardness and thermal conductivity of diamonds, manufacturers can enhance component quality, extend tool life, and improve overall machining efficiency, making diamond machining an indispensable technique in custom CNC machining.

66

66

Read more

Read more

VMT

VMT  2024 11 12

2024 11 12 The density of iron is approximately 7.87 g/cm³ (or 7,870 kg/m³). This fundamental property significantly impacts material selection, design calculations, and machining parameters in CNC machining services. Understanding iron's density ensures optimal performance and precision in manufacturing iron CNC machining parts.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!