15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 11 03

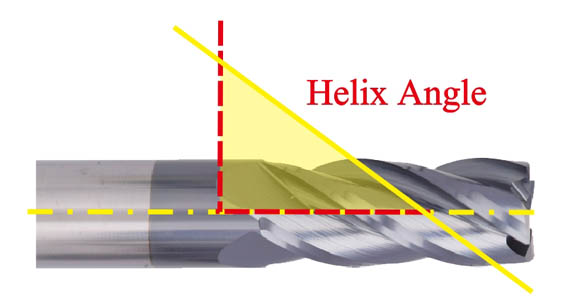

2024 11 03 A helix is a three-dimensional curve that spirals around an axis, forming a shape similar to a spring or a screw thread. In machining, helix angles refer specifically to the design of cutting tools, such as end mills and drill bits, where the cutting edge is designed in a helical pattern. This design is crucial for facilitating the movement of chips away from the cutting area, allowing for smoother operations and improved surface finishes.

66

66

Read more

Read more

VMT

VMT  2024 11 02

2024 11 02 Vapor polishing involves the use of vaporized solvents to smooth the surface of plastic parts. During the process, the workpiece is exposed to solvent vapors, which interact with the surface material. This interaction leads to the melting of the top layer of plastic, effectively leveling out any imperfections and creating a polished finish. Unlike traditional polishing methods that may introduce mechanical stress or require extensive manual labor, vapor polishing offers a gentler approach that is both efficient and effective.

66

66

Read more

Read more

VMT

VMT  2024 11 01

2024 11 01 Sheet metal hemming involves folding the edge of a metal sheet back onto itself. The purpose is to smoothen sharp edges and increase strength. It's widely used in sectors requiring high precision and durable components, such as automotive body panels, electronics, and appliance manufacturing. By combining functionality with aesthetics, hemming ensures product reliability and customer satisfaction.

66

66

Read more

Read more

VMT

VMT  2024 10 31

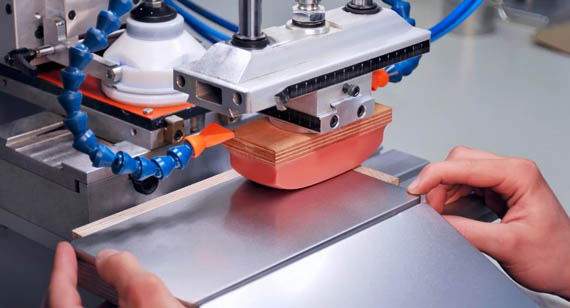

2024 10 31 Pad printing is an indirect offset printing process that transfers ink from a flat plate (cliché) to a 3D object using a flexible silicone pad. The silicone pad's adaptability allows it to transfer precise images onto flat, curved, or textured surfaces, making it ideal for applications like CNC machining parts or consumer products that require branding or functional labels. This versatile method is used across various industries, including automotive, electronics, medical devices, and sporting goods.

66

66

Read more

Read more

VMT

VMT  2024 10 30

2024 10 30 Are you struggling to achieve tight tolerances and flawless surface finishes in your machining operations? Precision grinding offers the perfect solution. This technique provides high accuracy and superior finishes, making it ideal for industries where perfection matters, such as aerospace, automotive, and medical manufacturing.

66

66

Read more

Read more

VMT

VMT  2024 10 29

2024 10 29 Having trouble choosing between thermoset and thermoplastic materials? Understanding the key differences between these polymers can help you select the right material for your manufacturing needs. Whether designing durable automotive parts or flexible consumer products, each type of plastic has unique advantages and disadvantages essential for your success.

66

66

Read more

Read more

VMT

VMT  2024 10 28

2024 10 28 CNC (Computer Numerical Control) machining is a cornerstone of modern manufacturing, enabling the precise fabrication of complex parts from various materials. Two crucial parameters that significantly affect the machining process are feed rate and cutting speed. Understanding the differences between these two concepts is vital for optimizing machining operations, enhancing productivity, and ensuring the longevity of tools. This guide will explore the definitions, optimal selections, and importance of feed rate and cutting speed in CNC machining, providing clarity for both novice and experienced machinists.

66

66

Read more

Read more

VMT

VMT  2024 10 27

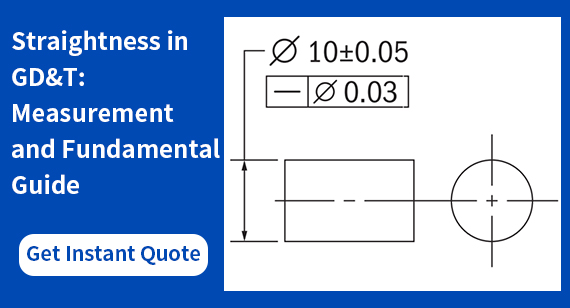

2024 10 27 Geometric Dimensioning and Tolerancing (GD&T) is an essential framework used in engineering to define and communicate the allowable variations in the shape and position of a part. Among its many features, straightness plays a pivotal role in ensuring that components fit together correctly and function as intended. Understanding straightness within the context of GD&T, including its definitions, measurement techniques, and applications, is crucial for manufacturers and engineers alike. This guide aims to provide a comprehensive overview of straightness in GD&T, offering insights into its measurement methods and practical implications in CNC machining.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!