15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 10 18

2024 10 18 Coolants are vital to CNC machining, not only for maintaining optimal temperatures but also for ensuring effective lubrication, extending tool life, and improving the surface finish of machined parts. This article provides a comprehensive look at the types of CNC machine tool coolants available, their uses across industries, the importance of selecting the right coolant, and the factors to consider when choosing the best coolant for CNC machining. Understanding coolants and their correct application can significantly impact both production efficiency and the longevity of CNC machinery.

66

66

Read more

Read more

VMT

VMT  2024 10 17

2024 10 17 In CNC machining services, the choice of material plays a critical role in the functionality and aesthetics of finished products. Translucent and transparent parts are frequently used in various industries, from consumer electronics and medical devices to automotive and industrial applications. Understanding the differences between translucent and transparent materials, their available types, and the machining processes suited to them is essential for ensuring optimal results.

66

66

Read more

Read more

VMT

VMT  2024 10 16

2024 10 16 Delrin, also known as polyoxymethylene (POM), is a popular thermoplastic used in a variety of industries due to its excellent machinability, strength, and durability. For CNC machining services, Delrin offers many advantages over other plastics and metals, making it a go-to material for both prototyping and high-volume production. However, working with Delrin requires specific techniques to ensure precision and optimal results. This guide will cover everything you need to know about Delrin machining, from its properties and applications to machining tips and finishing processes.

66

66

Read more

Read more

VMT

VMT  2024 10 15

2024 10 15 Bearings are one of the most essential components in mechanical systems, playing a crucial role in minimizing friction between moving parts and ensuring smooth rotational or linear motion. They are used in virtually every machine, from automobiles and airplanes to industrial machinery and household appliances. This article provides an in-depth look at the different types of bearings, their characteristics, advantages, disadvantages, and applications in various industries, including CNC machining parts manufacturing. Understanding the right bearing type for your application ensures optimal performance, longevity, and cost-efficiency.

66

66

Read more

Read more

VMT

VMT  2024 10 14

2024 10 14 In the field of CNC machining, tool steel is a key material for producing high-performance tools, dies, and components. Known for its hardness, durability, and ability to withstand extreme temperatures and wear, tool steel is widely used in industries that demand precision and toughness. Whether you're working on CNC prototype machining or large-scale manufacturing, selecting the right tool steel grade is critical to ensuring that your project meets performance and durability requirements.

66

66

Read more

Read more

VMT

VMT  2024 10 13

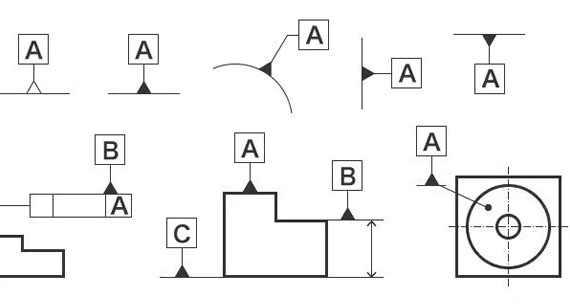

2024 10 13 In CNC machining and precision engineering, achieving accurate and repeatable measurements is vital for producing high-quality parts. This is where GD&T (Geometric Dimensioning and Tolerancing) plays a critical role. A key component of GD&T is the concept of datums, which serve as reference points or features that guide the manufacturing, inspection, and assembly processes. Datums are essential in defining how a part should be positioned or aligned in relation to its surroundings or other parts.

66

66

Read more

Read more

VMT

VMT  2024 10 12

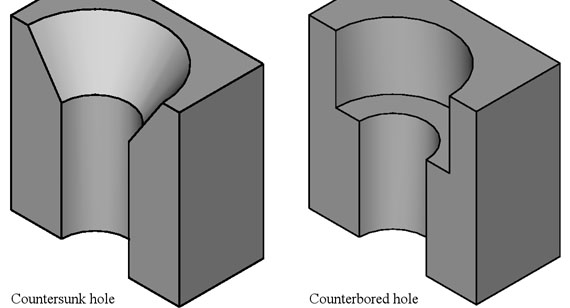

2024 10 12 In CNC machining, precision is key, especially when creating specific features on machined parts such as countersinks. A countersink is a conical hole cut into a material, typically metal, to allow the head of a screw, bolt, or fastener to sit flush with or below the surface of the workpiece. Countersinks are used in a wide range of applications in industries such as automotive, aerospace, electronics, and more.

66

66

Read more

Read more

VMT

VMT  2024 10 11

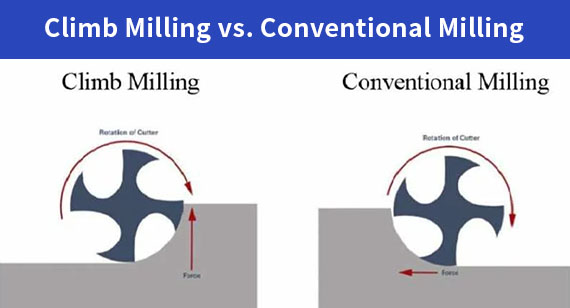

2024 10 11 In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!