15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 10 26

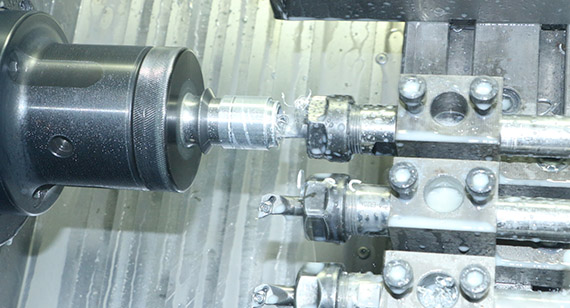

2024 10 26 CNC lathe slotting is a specialized machining process used to create grooves and slots in various materials, enhancing the functionality and aesthetics of parts. This process leverages advanced CNC technology to achieve high precision and repeatability, making it a vital operation in the manufacturing of components across diverse industries. Understanding the different types of slotting tools available, along with the methods and considerations for effective use, is essential for optimizing machining performance and ensuring high-quality results.

66

66

Read more

Read more

VMT

VMT  2024 10 25

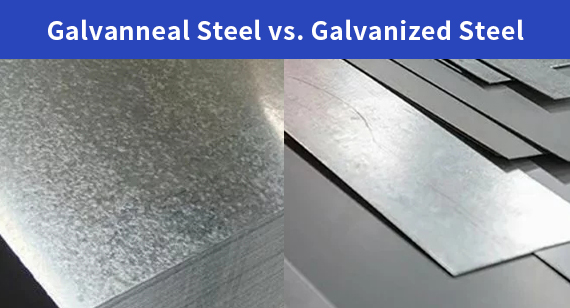

2024 10 25 In the world of sheet metal fabrication, choosing the right material is crucial to ensuring durability, cost-efficiency, and the desired performance of the final product. Two common materials that are often compared are Galvanneal steel and Galvanized steel. Both materials have undergone galvanization processes, which provide corrosion resistance by coating steel with zinc. However, the manufacturing processes, properties, and ideal applications for each material vary significantly.

66

66

Read more

Read more

VMT

VMT  2024 10 24

2024 10 24 In the rapidly evolving landscape of manufacturing, CNC robots have emerged as a transformative force, reshaping the way components are machined and assembled. These automated systems offer unparalleled precision, efficiency, and flexibility, making them an essential tool in modern manufacturing environments. This article delves into the intricacies of CNC robots, exploring their functionalities, advantages, and the pivotal role they play in automated machining processes.

66

66

Read more

Read more

VMT

VMT  2024 10 23

2024 10 23 Magnesium CNC machining is a specialized process that requires a thorough understanding of both the material's properties and the best practices to ensure safe and effective machining. Magnesium, known for its lightweight and high-strength characteristics, has found applications across various industries, including aerospace, automotive, and electronics. However, its unique properties also introduce specific risks that must be managed effectively. This article aims to provide an overview of magnesium, its machinability, associated risks, and essential safety guidelines for CNC machining.

66

66

Read more

Read more

VMT

VMT  2024 10 22

2024 10 22 In the realm of manufacturing, anodized aluminum stands out for its unique blend of functionality and aesthetics. This specialized finish transforms raw aluminum into a material that is not only visually appealing but also highly durable and resistant to corrosion. Anodizing enhances the properties of aluminum, making it an ideal choice for a wide range of applications, from aerospace components to consumer electronics. As an expert in CNC machined parts manufacturing, understanding anodized aluminum is essential for delivering quality products that meet the demands of various industries. This article will provide an in-depth exploration of anodized aluminum, its processes, benefits, limitations, and applications, ensuring that you have all the knowledge you need to leverage this remarkable material in your projects.

66

66

Read more

Read more

VMT

VMT  2024 10 21

2024 10 21 In the world of manufacturing, tools are the backbone that supports the production of precision components and products. Tools in manufacturing encompass a wide variety of instruments and machinery designed to assist in the fabrication, assembly, and finishing of items. Whether it’s the cutting tools used in CNC machining or the molds utilized for injection molding, the right tools are critical to ensuring the efficiency, accuracy, and quality of the final product. This article will delve into what tools in manufacturing are, their importance, types, cost considerations, and more, providing a comprehensive understanding for professionals and enthusiasts alike.

66

66

Read more

Read more

VMT

VMT  2024 10 20

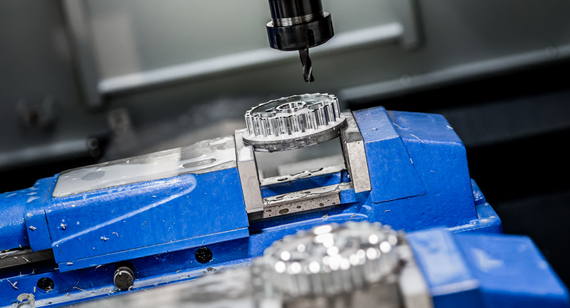

2024 10 20 End milling is a critical process in CNC machining that allows for high-precision cutting and shaping of various materials. With its ability to perform intricate designs and complex geometries, end milling has become an essential operation in the manufacturing sector, especially in industries that require custom CNC machined parts. This article delves into the different types of end mills, their applications, advantages, and processes involved in end milling.

66

66

Read more

Read more

VMT

VMT  2024 10 19

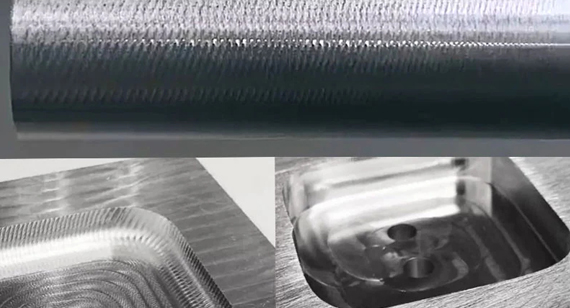

2024 10 19 In machining, vibrations can significantly affect quality, tool life, machine longevity, and productivity. Understanding the origins, consequences, and methods for reducing or avoiding vibration is essential to achieving precise and efficient machining results. By addressing vibration issues, manufacturers can optimize performance, minimize operational disruptions, and meet high standards in dimensional accuracy and surface finish quality.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!