15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 10 10

2024 10 10 In CNC machining, milling cutter tools are essential for shaping, cutting, and removing material from a workpiece. Whether you're working on CNC prototype machining or large-scale production, selecting the right type of milling cutter ensures precision, efficiency, and a high-quality finish. With a wide variety of milling tools available, understanding their types, features, and applications is crucial to making informed choices in a CNC machining factory.

66

66

Read more

Read more

VMT

VMT  2024 10 09

2024 10 09 In the world of custom CNC machining, the selection of machine tools plays a crucial role in achieving precision, accuracy, and efficiency. Whether you are producing complex parts for aerospace, automotive, or medical devices, choosing the right type of CNC machine tool is essential for meeting production goals and maintaining high-quality standards. With technological advancements, CNC machine tools have diversified, offering a range of functionalities for different applications.

66

66

Read more

Read more

VMT

VMT  2024 10 08

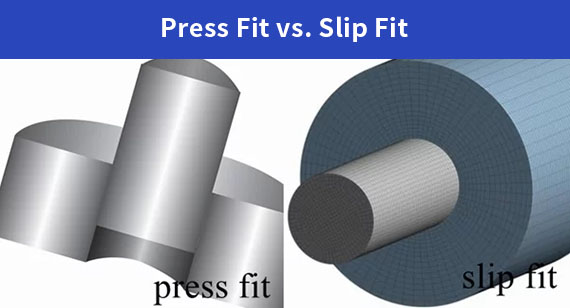

2024 10 08 In CNC machining and precision engineering, achieving the correct fit between two parts is critical for ensuring the reliability, performance, and longevity of assemblies. Two commonly used fitting methods are press fit and slide fit, each offering different characteristics in terms of force required for assembly, the degree of tightness between mating parts, and their respective applications. These fits are essential in areas like machinery, automotive components, and aerospace parts where high precision is necessary for both fixed and movable parts.

66

66

Read more

Read more

VMT

VMT  2024 10 07

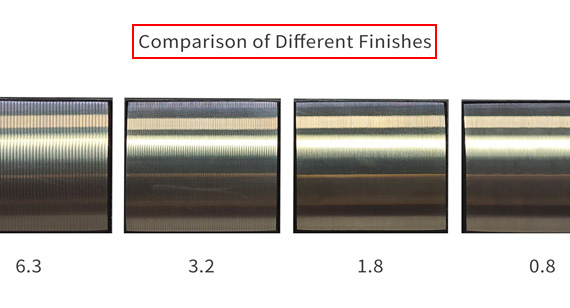

2024 10 07 In CNC precision machining, surface roughness plays a crucial role in determining the quality, performance, and durability of machined parts. Surface roughness refers to the small deviations in the texture of a machined surface. These deviations, while often imperceptible to the naked eye, can significantly affect the part’s functionality, lifespan, and aesthetic appeal.

66

66

Read more

Read more

VMT

VMT  2024 10 06

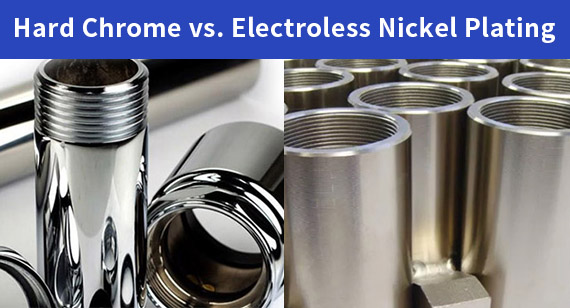

2024 10 06 In the world of CNC precision machining, surface treatments like plating are essential for enhancing the durability, corrosion resistance, and overall performance of metal components. Among the many plating options available, hard chrome and chemical nickel plating are two popular methods that offer different benefits and characteristics. Selecting the right plating process depends on the application, the environment, and the desired performance characteristics of the component.

66

66

Read more

Read more

VMT

VMT  2024 10 05

2024 10 05 Aluminum is a widely used material in industries such as aerospace, automotive, and construction due to its lightweight, corrosion resistance, and high strength-to-weight ratio. While it offers numerous advantages, welding aluminum is notoriously challenging. Welding aluminum requires special techniques, equipment, and knowledge to avoid issues such as oxidation, porosity, and cracking. Mastering aluminum welding is essential for achieving high-quality, durable welds, particularly in CNC precision machining and fabrication.

66

66

Read more

Read more

VMT

VMT  2024 10 04

2024 10 04 Metal polishing is an essential process in manufacturing, providing not only aesthetic appeal but also enhancing the durability and functionality of metal components. Whether it’s for CNC machined parts or custom metal fabrications, polishing ensures that surfaces are smooth, free of imperfections, and resistant to corrosion or wear. Polished metals are commonly used in industries such as automotive, aerospace, electronics, and household goods, where both appearance and performance matter.

66

66

Read more

Read more

VMT

VMT  2024 10 03

2024 10 03 Metal laser engraving has become an indispensable technology in industries requiring precision and durability in their components. From manufacturing logos and serial numbers to creating intricate patterns, laser engraving offers a versatile and efficient way to mark metal surfaces. Its applications span across various sectors, including aerospace, automotive, medical devices, and electronics. Whether you're working with CNC machining parts or high-precision prototypes, metal laser engraving provides a clean, permanent marking solution that withstands environmental stressors and wear over time.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!