15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 11 11

2024 11 11 The density of red copper is approximately 8.96 g/cm³. This high density contributes to its excellent electrical and thermal conductivity, making it an ideal material for CNC machining parts in industries like electronics, aerospace, and automotive. Understanding red copper's density is crucial for precise calculations and optimal performance in custom CNC machining projects.

66

66

Read more

Read more

VMT

VMT  2024 11 10

2024 11 10 The density of stainless steel typically ranges between 7,750 kg/m³ and 8,050 kg/m³, depending on its grade and composition. This density is crucial in CNC machining as it affects material selection, machining parameters, and overall product performance. Understanding stainless steel's density ensures optimal design and manufacturing in CNC machining services.

66

66

Read more

Read more

VMT

VMT  2024 11 09

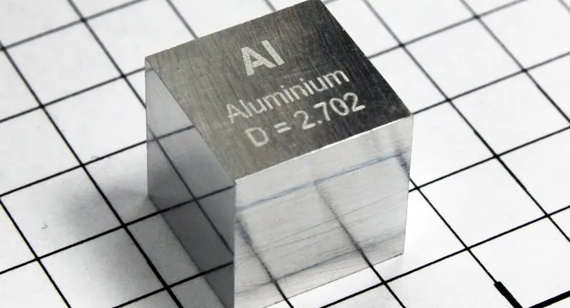

2024 11 09 The density of aluminum is approximately 2.70 g/cm³, making it one of the lightest commercially available metals. This low density is crucial in CNC machining parts manufacturing, as it allows for the production of lightweight yet strong components, improving performance and fuel efficiency in industries like aerospace and automotive.

66

66

Read more

Read more

VMT

VMT  2024 11 08

2024 11 08 The melting point of steel ranges from approximately 1,370°C to 1,530°C (2,500°F to 2,790°F), depending on its composition. Understanding this range is crucial for CNC machining services to prevent material deformation, ensure precision in CNC prototype machining, and produce high-quality steel CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2024 11 07

2024 11 07 The melting point of iron is 1,538°C (2,800°F). This high temperature is a critical factor for industrial applications involving CNC machining parts, casting, and smelting. The precise understanding of iron’s melting point ensures optimal performance in manufacturing processes, allowing for effective production of durable and reliable iron CNC machining components.

66

66

Read more

Read more

VMT

VMT  2024 11 06

2024 11 06 Stainless steel’s melting point ranges between 1,375°C and 1,530°C depending on the alloy grade, with 304 and 316 grades among the most commonly used. This high melting range allows stainless steel to maintain strength and stability under extreme heat, making it ideal for high-temperature environments and demanding applications.

66

66

Read more

Read more

VMT

VMT  2024 11 05

2024 11 05 Titanium has a melting point of approximately 1,668°C (3,034°F), or 1,941 Kelvin, placing it among metals with higher melting points compared to more commonly used metals like aluminum or copper. The relatively high melting point enables titanium to withstand extreme temperatures, which is crucial for applications in fields like aerospace and power generation. The ability of titanium to endure high temperatures without deformation or loss of strength makes it a top choice for manufacturing CNC machining parts used in harsh environments.

66

66

Read more

Read more

VMT

VMT  2024 11 04

2024 11 04 The importance of strength, stiffness, and hardness cannot be overstated in manufacturing processes. These properties directly influence the performance and reliability of components and structures. Strength refers to the ability of a material to withstand applied forces without deformation or failure. Stiffness measures a material's resistance to elastic deformation under load, which is essential for maintaining dimensional accuracy during machining. Hardness indicates how well a material resists surface deformation, wear, and scratching, making it a vital property for tools and components subject to abrasive conditions.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!