15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 12 05

2024 12 05 Assembly Design Principles, integral to Design for Assembly (DFA), focus on simplifying product structures, minimizing part counts, and optimizing assembly processes. These principles enhance efficiency, reduce costs, and improve product reliability, making them essential for effective CNC machining parts assembly and overall manufacturing excellence.

66

66

Read more

Read more

VMT

VMT  2024 12 04

2024 12 04 CAD (Computer-Aided Design) revolutionizes rapid prototyping by providing precise digital models, enhancing design accuracy, accelerating production cycles, and enabling seamless integration with CNC machining and other manufacturing technologies. This ensures efficient development and high-quality outcomes in various industries.

66

66

Read more

Read more

VMT

VMT  2024 12 03

2024 12 03 CNC machining enhances the energy industry by delivering high-precision parts, improving production efficiency, and offering material versatility, which collectively contribute to increased reliability and cost-effectiveness in both renewable and non-renewable energy applications.

66

66

Read more

Read more

VMT

VMT  2024 12 02

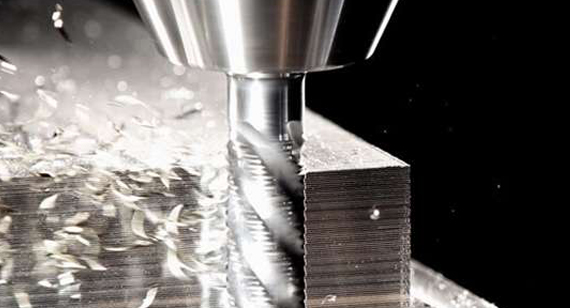

2024 12 02 Different hole types in CNC machining—such as through holes, blind holes, tapped holes, and counterbores—play a vital role in parts manufacturing. Choosing the appropriate hole type ensures optimal part performance, manufacturing efficiency, and cost-effectiveness in CNC machining services.

66

66

Read more

Read more

VMT

VMT  2024 12 01

2024 12 01 CNC machining stainless steel parts comes with its own set of challenges, including high heat generation, tool wear, and machining precision. Specialized techniques like managing heat and using the right cutting tools can help overcome these issues. Choosing the right grade of stainless steel and machining method is essential for achieving high-quality results, making custom CNC machining services crucial for complex stainless steel parts.

66

66

Read more

Read more

VMT

VMT  2024 11 30

2024 11 30 Medical robots, from surgical systems to rehabilitation aids, are increasingly used in healthcare for their precision and ability to assist in complex tasks. Precision manufacturing technologies, such as CNC machining, 3D printing, and molding processes, are essential to producing the high-quality components required for these robots. Whether you're creating CNC processed medical robot parts or considering CNC prototype processing for a new design, choosing the right manufacturing method ensures safety, accuracy, and performance.

66

66

Read more

Read more

VMT

VMT  2024 11 29

2024 11 29 CNC robots combine the precision of CNC machining with the flexibility of automated robots, enabling manufacturers to automate complex tasks, improve accuracy, reduce labor costs, and increase production efficiency, making them a game-changer in modern manufacturing.

66

66

Read more

Read more

VMT

VMT  2024 11 28

2024 11 28 Radiator design involves creating components that effectively dissipate heat from electronic devices by maximizing surface area, selecting appropriate materials like aluminum or copper, and optimizing fin geometry to enhance thermal performance, ensuring device reliability and efficiency.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!