15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 09 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 09 2026 | Reading Time:About 2 minutes

4043 aluminum is a widely used silicon-aluminum filler alloy possessing excellent flow, crack resistance, and silvery-white weld appearance. It is truly a popular choice for welding 6XXX series aluminum alloys, cast aluminum, and general fabrication projects. Besides being used as welds, it is also made into functional and decorative components across many industries for its moderate strength, good corrosion resistance, and affordable cost.

This guide will provide you with a comprehensive understanding of 4043 aluminum composition, properties, forms, essential welding tips, applications, as well as comparing it to other alloys. Read on to learn more details about 4043 aluminum.

4043 aluminum is a specialized aluminum-silicon filler alloy engineered for excellent weldability and crack resistance. While it is not intended for high-strength structural applications, its superior flow, reduced cracking, and bright silvery weld finish make it highly suitable for aluminum fabrication. Additionally, its moderate strength and good corrosion resistance allow it to be used across a wide range of industrial and manufacturing applications like automotive, marine, or general aluminum projects.

Key Features of 4043 Aluminum:

4043 aluminum composition consists primarily of aluminium as the base and around 4.5 – 6.0% silicon contributing to welding performance, with small amounts of other elements to fine-tune properties:

Table 1: Chemical Composition of 4043 Aluminum (Typical Limits)

| Element | Composition (wt %) |

| Aluminum (Al) | Balance |

| Silicon (Si) | 4.5 – 6.0 |

| Iron (Fe) | ≤ 0.60 |

| Copper (Cu) | ≤ 0.30 |

| Titanium (Ti) | ≤ 0.15 |

| Zinc (Zn) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.15 |

| Magnesium (Mg) | ≤ 0.20 |

| Other (each) | ≤ 0.05 |

| Other (total) | ≤ 0.15 |

The silicon content in 4043 aluminum improves weld puddle fluidity, enhances crack resistance, and produces a bright, silvery-white weld appearance.

Several international equivalents of 4043 aluminium that vary slightly in minor elements but share the same silicon-dominant composition, including EN AW-4043 (Europe), AA 4043 (US), JIS A4043 (Japan), GOST 4043 (Russia), AS 4043 (Australia), NS-4043 (Norway), BS 4043 (UK), and DIN 4043 (Germany).

4043 aluminum exhibits a combination of mechanical, thermal, and metallurgical properties that make it highly versatile for welding and fabrication.

Table 2: Properties of 4043 Aluminum

| Property | Metric | Imperial |

| Density | 2.69 g/cm³ | 0.0972 lb/in³ |

| Tensile Strength | 145 MPa | 21,000 psi |

| Yield Strength | 70 MPa | 10,200 psi |

| Elongation at Break | 22% | 22% |

| Poisson’s Ratio | 0.34 | 0.34 |

| Shear Strength | 90 MPa | 13,100 psi |

| Hardness (Brinell) | 39 HB | 39 HB |

| Thermal Expansion Coefficient | 22.1 µm/m·°C | 12.3 µin/in·°F |

| Thermal Conductivity | 163 W/m·K | 1130 BTU·in/hr·ft²·°F |

Mechanical Properties:

Thermal Properties:

Metallurgical Properties:

4043 aluminum is available in various forms to meet different machining, fabrication and welding requirements:

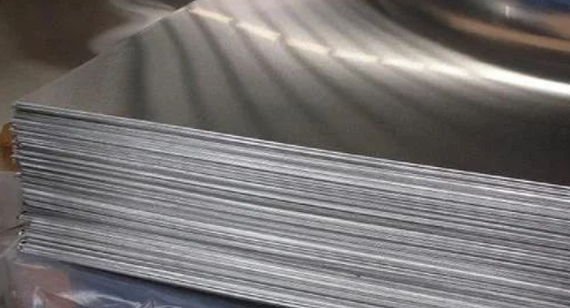

4043 Aluminum Sheet

This form is typically used for flat components such as panels, enclosures, and formed parts where good weldability and surface finish are important.

4043 Aluminum Rod

It is commonly used for precision-machined components produced through turning, milling, and other CNC machining operations, where dimensional accuracy is required, and compatibility with subsequent welding may be needed.

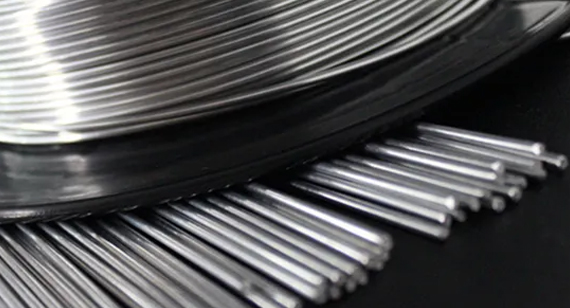

4043 Aluminum Wire

It serves as a general-purpose filler material for aluminum repair, maintenance, and light fabrication tasks.

4043 Filler Rod and TIG Rod

They are manufactured specifically for TIG welding applications, allowing precise control of the weld pool and heat input (precise control of the molten metal and heat during welding).

ER 4043 Aluminum MIG Wire

This form is designed for continuous-feed MIG welding applications, providing stable arc performance(helping achieve consistent, high-quality welds with minimal spatter) and consistent weld quality.

4043 aluminum is highly versatile for MIG (GMAW) and TIG (GTAW) welding, performing well in all welding positions and accommodating thin, moderately thick, and rod-shaped aluminum components.

Here’s how to weld with 4043 aluminum using a bar as an example:

Step 1: Surface Preparation

You will clean the aluminiium bar surface thoroughly to remove oxides, dirt, and other contaminants. A clean surface ensures proper weld fusion and minimizes porosity.

Step 2: Shielding Gas

You need to use 100% argon for both TIG and MIG welding to protect the molten weld pool from atmospheric contamination.

Step 3: Torch Technique

Then, it’s necessary to maintain a steady torch angle to ensure even heat distribution and consistent weld penetration across the joint.

Step 4: Filler Rod Feeding

Next is to feed the 4043 filler rod consistently into the weld pool. For TIG welding, select a rod matched to the base metal thickness.

Step 5: Cooling

Final step is to allow the weld to cool naturally at room temperature. Gradual cooling helps minimize thermal stress, distortion, and cracking.

Tips for Best Results:

Understanding the differences between 4043 and other alloys can help you select the most suitable material for your parts or filler for each application, whether for welding, fabrication, or structural purposes. The following table compares 4043, 4047, 5356, and 6061 aluminum, highlighting the adaptability of welding and structural uses for each alloy:

Table 3: Comparison of 4043 vs 4047 vs 5356 vs 6061 Aluminum

| Alloy | Strength | Corrosion Resistance | Welding Performance | Structural Suitability | Relative Cost |

| 4043 | Moderate | Medium | Excellent; bright silver welds | Moderate | Low |

| 4047 | Moderate | Medium | Good; smooth welds | Less common for structural use | Medium |

| 5356 | High | High | Good; slightly darker welds | Excellent for structural use | High |

| 6061 | High | Medium | Weldable, strength may decrease after welding | Good for structural use | Medium |

Cost Differences Among Aluminum Alloys

4043 aluminum, with silicon as its main alloying element, has abundant raw material, mature processing, and stable market supply, making it relatively low in cost. 4047 contains higher silicon, requiring stricter melting and composition control, and its production volume is limited, resulting in medium cost. 5356, with high magnesium content, uses a more energy-intensive and price-volatile alloying element and requires stricter welding and material consistency, leading to higher overall cost. 6061 has widely available material and moderate unit price, but post-weld reinforcement or heat treatment is often necessary, keeping its comprehensive cost at a medium level.

Welding Performance and Structural Suitability

Silicon-based alloys (4043 and 4047) have excellent weld fluidity and low sensitivity to hot cracking, producing bright, smooth welds, but the weld and base material strength are limited. They are suitable as filler materials or for non-load-bearing components. 5356 retains high strength after welding, making it suitable for structural welds such as automotive frames and marine applications. 6061 is a typical structural alloy, but post-weld heat-affected zones can reduce strength, often requiring design reinforcement or heat treatment to maintain performance.

Appearance and Post-Processing Considerations

4043 and 4047 produce bright, smooth welds, ideal for decorative parts or applications with high cosmetic requirements. 5356 welds are slightly darker with less uniform appearance but offer superior load-bearing capacity. 6061 welds may require additional post-processing to meet both structural and assembly requirements.

4043 aluminum’s moderate strength, good corrosion resistance, and cost-effectiveness make it suitable for a wide range of applications. Common examples include:

4043 aluminum is a silicon-based filler alloy valued for its high fluidity, excellent crack resistance, and attractive weld appearance. While it does not offer the high strength of magnesium-based alloys like 5356, its versatility in MIG and TIG welding applications, compatibility with multiple forms (sheets, rods, wires), and wide application range make it a staple in fabrication and CNC machining.

Client Challenge

An American automotive supplier required 4043 aluminum structural and decorative components with complex geometries and tight tolerances (±0.05 mm).

The alloy’s high fluidity during welding increased the risk of cracking and post-weld distortion, making it difficult for conventional machining and standard welding parameters to deliver consistent quality within the required schedule.

Solution

Machining Process Optimization

Cutting parameters and tool paths were adjusted to match 4043 aluminum’s thermal and cutting behavior, reducing localized heat buildup and edge deformation. Compared with initial trial runs, dimensional variation was reduced by approximately 30%.

Customized Welding Control

MIG/TIG welding parameters were specifically tuned to control weld pool fluidity and heat input, improving weld stability on thin and complex sections. As a result, no visible weld cracking was observed throughout production.

Inspection and Finishing Integration

First-article and in-process inspections were conducted using CMM to ensure dimensional consistency, followed by post-weld cleaning and surface blending to meet both structural and cosmetic requirements. The process achieved a first-pass yield above 98%.

Results

Q1: What is the price of 4043 aluminum?

Prices vary depending on the supplier, product form (rod, wire, sheet), and current market conditions. You can contact your supplier for the latest pricing and bulk order discounts.

Q2: Is 4043 aluminum available for sale?

Yes, 4043 aluminum is widely available worldwide in various forms, including rods, TIG filler rods, MIG wires, sheets, and plates.

Q3: What is the difference between 4043 and 6061 aluminum?

6061 aluminum is stronger and heat-treatable, making it suitable for structural applications. 4043, on the other hand, is primarily used as a filler alloy for welding, offering excellent corrosion resistance and ease of use.

Q4: Which is better for welding 6061 aluminum, 4043 or 5356?

4043 aluminum is referred for better crack resistance and smoother weld appearance. 5356 offers higher strength and is used when maximum weld strength is required.

Q5: Can 6061 aluminum be welded with 4043 wires?

Yes, 4043 wire is commonly used for MIG or TIG welding 6061 aluminum, particularly in automotive, structural, and general fabrication applications.

Q6: How corrosion-resistant is 4043 aluminum?

4043 aluminum offers excellent corrosion resistance, especially against atmospheric corrosion and in marine environments. This makes it ideal for automotive, marine, and construction applications where durability and longevity are important.