15 years one-stop China custom CNC machining parts factory

1 |

Published by VMT at Jan 13 2026 | Reading Time:About 2 minutes

1 |

Published by VMT at Jan 13 2026 | Reading Time:About 2 minutes

You may have heard 6063 alloy that’s often called the extruded aluminum alloy, which is especially popular in building aluminum profile industry. But, about this member of the 6xxx series alloy, it’s not only for the alloy’s characteristics of outstanding extrudability, corrosion resistance, and weldability, but also for it’s differences of properties under T5 / T52 / T6 temper effect its value in engineering and manufacturing. For a more detailed discussion about aluminum 6063 alloys, you will find more in the sections below.

Aluminum Association has set up the technical standards for 6xxx aluminum, whose main alloying elements are magnesium (Mg) and silicon (Si), along with strength enhancement through Mg₂Si precipitation. 6063 aluminum precisely belongs to the Al–Mg–Si (6xxx series) wrought alloys, which is a typical heat-treatable alloy. For example, T6 temper has undergone solution heat treatment, quenching, and artificial aging, maximizing the precipitation of Mg₂Si, finally giving 6063 a higher strength.

However, for its engineering positioning, 6063 aluminum is generally considered a medium-strength alloy, and heat treatment strengthening is just one of its characteristics. Its excellent extrudability, surface quality, and corrosion resistance are the main advantages of aluminum 6063 in practical applications.

Therefore, typical applications of 6063 aluminum are not high-strength structural components, but rather complex-profile extrusions, high-appearance anodized parts, and structures exposed long-term to mild corrosive environments together with medium loads.

This Al–Mg–Si alloy mainly depend on its elements of Mg (Magnesium) and Si (Silicon) to improve its strength; while low content of Cu (Copper) gives 6063 aluminum a higher corrosion resistance but this comes at the cost of a lower strength limit ; and Fe (Iron) is to balance strength, extrusion flowability, and surface quality. Chemical composition of 6063 aluminum include:

Table 1: Chemical Composition of 6063 Aluminum Alloy

| Element | Content (wt.%) |

| Si (Silicon) | 0.20 – 0.60 |

| Mg (Magnesium) | 0.45 – 0.90 |

| Fe (Iron) | ≤ 0.35 |

| Cu (Copper) | ≤ 0.10 |

| Mn (Manganese) | ≤ 0.10 |

| Cr (Chromium) | ≤ 0.10 |

| Zn (Zinc) | ≤ 0.10 |

| Ti (Titanium) | ≤ 0.10 |

| Al (Aluminum) | Balance |

T5、T52 and T6 Tempers of 6063 Aluminum

The mechanical properties of 6063 aluminum are highly dependent on its temper (heat treatment condition), while its physical and thermal properties remain constant. The most common tempers are T5, T52, and T6:

Typical Physical, Mechanical and Thermal Properties of 6063 Aluminum

Below is a quick overview of 6063 aluminum’s physical, Mechanical and Thermal properties:

Table 2: Properties of 6063 Aluminum Alloy

| Category | Property | 6063‑T5 | 6063‑T52 | 6063‑T6 |

| Mechanical |

Ultimate Tensile Strength (MPa) | ≈ 145–200 | ≈ 150–200 | ≈ 190–290 |

| Yield Strength (0.2% offset, MPa) | ≈ 110–155 | ≈ 115–160 | ≈ 160–240 | |

| Elongation at Break (%) | ≈ 8–12 | ≈ 8–12 | ≈ 8–12 | |

| Hardness (HB) | ≈ 60–75 | ≈ 65–75 | ≈ 75–85 | |

| Physical | Density (g/cm³) | 2.70 | 2.70 | 2.70 |

| Thermal |

Thermal Conductivity (W/m·K) | ≈ 190–220 | ≈ 190–220 | ≈ 190–220 |

| Melting Range (°C) | ≈ 615–655 | ≈ 615–655 | ≈ 615–655 |

1. Mechanical Properties

Yield strength is the maximum stress a material can withstand before it begins to deform plastically. For 6063 aluminum, it is medium but can be increased through T6 heat treatment. This property is essential for designing medium-load structural components of 6063 aluminum, such as roof framing, railing, and handrail.

Ultimate tensile strength represents the maximum stress a material can sustain before breaking. 6063 aluminum exhibits medium tensile strength. It is used to evaluate the maximum load the 6063 aluminum component can handle in tension.

Elongation at break measures a material's ability to stretch before fracture, reflecting its plasticity and ductility. 6063 aluminum has moderate to high elongation, which allows the aluminum extruded profiles to undergo forming, bending, or machining without cracking.

Hardness indicates the resistance of a material to localized plastic deformation. 6063 aluminum has medium hardness, which gives it moderate wear resistance and good machinability. While it is not suitable for high-friction or long-term wear components, such as bearings or gears, in light-load or decorative applications—such as architectural profiles and tubing surfaces—it is easy to work with and performs stably, resisting scratches and surface wear.

2. Physical Properties

Density is the mass of a material per unit volume. 6063 aluminum has a low density, which makes it ideal for lightweight designs such as architectural profiles, tubing, and lightweight structural parts.

3. Thermal Properties

Thermal conductivity measures a material’s ability to conduct heat. 6063 aluminum has relatively high thermal conductivity, which is beneficial for heat dissipation applications, heat exchangers, or structural parts where uniform temperature distribution is important.

The melting range defines the temperature range in which a material transitions from solid to liquid. For 6063 aluminum, it is medium. This property guides heat treatment, welding, and manufacturing processes by defining the safe temperature limits during thermal processing.

Moderate Strength but Easy to Manufacture

Moderate strength of aluminum 6063 alloy and enhanced strength after heat treatment is sufficient for applications of:

If your engineering purpose is “adequate, stable, and easy to manufacture” rather for maximum strength design, aluminum 6063 is highly suitable for your components where consistent performance, formability, and fabrication efficiency are more important than extreme mechanical properties.

Excellent Corrosion Resistance

Low copper content, natural formation of protective oxide layer, and its stable Mg–Si system contributes to 6063 aluminum’s excellent corrosion resistance. Low copper content reduces susceptibility to electrochemical corrosion, and the precipitated phases of Mg–Si system are relatively resistant to corrosion.

Thus, 6063 aluminum performs engineering advantages that:

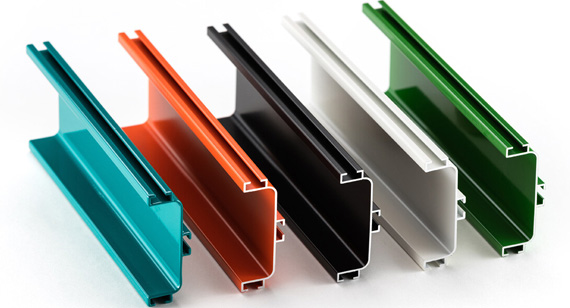

Superior Extrudability

6063 aluminum is well known for its superior extrudability. It is regarded as one of the most suitable alloys for complex extrusion profiles, particularly in the form of 6063 T5 extruded aluminum. This is not only for it’s composition and medium strength provide excellent flow characteristics during extrusion, but also because the T5 temper offers good dimensional stability and consistent mechanical properties immediately after artificial aging. So, 6063-T5 aluminum is highly suitable for precision architectural profiles and decorative extrusions.

Good to Excellent Weldability

6063 aluminum alloy exhibits good to excellent weldability, mainly because of its low copper content and well-balanced Mg–Si composition, which help reduce hot-cracking sensitivity and provide a stable weld pool. It is well suited for TIG and MIG welding, and commonly paired with ER4043 or ER5356 filler wires. But if your application is a little sensitive to strength (uses of 6063-T6), post-weld heat treatment or structural reinforcement may be required to restore performance, as welding will locally reduce the strength of 6063-T6 in the heat-affected zone.

The surface quality of 6063 aluminum is one of its key competitive advantages. It naturally produces a smooth, fine-textured, and bright surface, making it especially suitable for anodizing. After anodizing, the oxide layer is uniform and consistent, with minimal color variation. So, 6063 is widely used in applications where appearance and surface finish are valued, such as decorative structure or shelf, display rack.

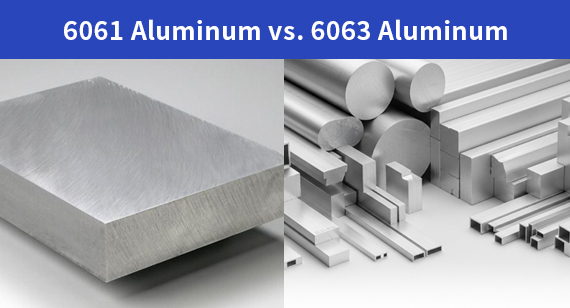

As the two most common and widely used aluminum alloys, 6063 aluminum and 6061 aluminum differ in their properties, uses, and cost. Key differences of 6063 and 6061 aluminum are shown in below table:

Table 3: Comparison of 6063 Aluminum vs 6061 Aluminum

| Item | 6063 Aluminum | 6061 Aluminum |

| Strength (Tensile / Yield) | Medium | Higher |

| Typical Tensile | ~190–290 MPa (T6) | ~310–350 MPa (T6) |

| Typical Yield | ~160–240 MPa (T6) | ~275–310 MPa (T6) |

| Corrosion Resistance | Excellent | Good |

| Extrudability | Excellent | Good |

| Surface Finish | Excellent uniform and bright finish | Fair to good surface but less uniform after anodizing |

| Weldability | Good | Good but slightly more sensitive to hot cracking |

| Typical Applications | Architectural profiles, decorative structures, light-to-medium framing | Structural components, high-strength frames, load-bearing parts |

| Relative Cost | Generally lower | Generally higher |

Strength Differences

Aluminum 6061(T6 heat-treated) outperforms 6063(T6) in both tensile and yield strength, making it preferable for structural load-bearing applications. Aluminum 6063’s strength in T6 is still adequate for many architectural and structural uses that do not require maximum load capacity.

Corrosion Differences

Aluminum 6063’s extremely low copper content and stable Mg–Si system yields better atmospheric corrosion resistance than 6061, especially in outdoor environments.

Extrudability & Surface Finish

Aluminum alloy 6063’s chemistry promotes excellent flow during extrusion, producing smooth, defect-free profiles even with intricate geometries. This also contributes to superior anodized surface quality, with fewer color variations and a more consistent finish compared to 6061 aluminum alloy.

Weldability Differences

Both alloys are weldable by MIG/TIG, but aluminum alloy 6063’s lower hot-cracking sensitivity often makes it easier to achieve consistent welds without specialized procedures.

Cost Differences

6063 aluminum alloy is generally less expensive than 6061 due to its simpler alloying composition. Besides the material itself, large-scale production volume of 6063 aluminum products also lowers its price due to the strong market competition. But you may note that market prices still vary with aluminum commodity pricing and specific processing requirements. Another factor is processing cost that 6063 aluminum is easier to extrude and machine, so the processing cost of 6063 is relatively lower.

Architectural and Decorative Structures

6063 aluminum is widely used in architectural and decorative applications due to its excellent surface finish and corrosion resistance. Typical uses include window frames, door frames, curtain wall systems, roof structures, signage frames, and decorative trims, where appearance and long-term outdoor performance are critical.

Architectural Functional Structures

Beyond decorative purposes, 6063 aluminum is also applied in functional architectural components such as railings, handrails, stair systems, and load-bearing elements with high aesthetic requirements. In these applications, the alloy provides sufficient strength while maintaining a clean and uniform appearance.

Tubing and Extruded Profile Applications

Thanks to its superior extrudability, 6063 is commonly manufactured as 6063 aluminum tubing and 6063 aluminum pipes. These forms are widely used in irrigation systems, light fluid transport, and structural support systems, especially where complex cross-sections and dimensional consistency are required.

Furniture and Display

6063 aluminum is frequently used in indoor and outdoor furniture, as well as shelving and display uses. Its lightweight nature, ease of fabrication, and attractive surface finish make it suitable for both functional and design-oriented products.

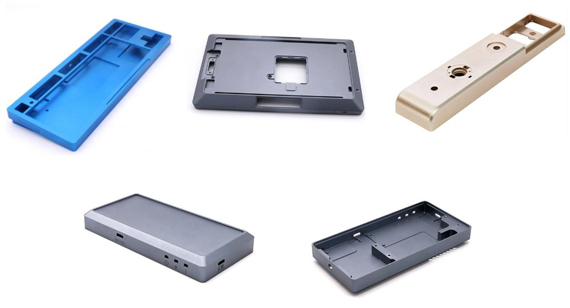

Industrial and Electrical Equipment

In industrial applications, 6063 aluminum is used for heat exchangers, electrical enclosures, and conveyor systems, where corrosion resistance, thermal conductivity, and formability are important. 6063 aluminum plate is also used for lightweight structural components and panel applications that do not require high mechanical strength.

In summary, if your project focuses on complex cross-sections, high-quality surface finishes, long-term outdoor durability, and a balanced combination of cost and manufacturability, 6063 aluminum is an ideal alloy. Excellent extrudability, appearance, and environmental stability of your 6063 aluminum applications can be achieved through this material.

Client Challenge

A North American industrial equipment company required the production of 6063 aluminum heat exchanger core components. The parts featured complex internal channels with thin walls (1.5–2 mm) and demanded high dimensional accuracy (±0.02–0.03 mm) along with smooth surfaces to ensure optimal fluid flow and corrosion resistance. Previous vendors struggled to simultaneously achieve thin-wall complex channel machining, dimensional precision, and surface quality, leading to high rework rates and inconsistent delivery schedules.

VMT CNC Machining Factory Solution

VMT addressed these challenges through multi-axis CNC machining combined with specialized fixturing, completing complex channel features in a single setup. Cutting speeds, feeds, and tool paths were optimized to minimize heat accumulation and local distortion, ensuring uniform wall thickness and dimensional stability. Post-machining, CMM inspection, polishing, cleaning, and transitional surface treatment were applied to guarantee smooth surfaces and burr-free internal channels, providing an ideal substrate for downstream assembly and anodizing. T5 extruded components underwent artificial aging and stress-relief treatment, maintaining medium strength while improving dimensional stability and corrosion resistance.

Project Results

All components met the tight ±0.02–0.03 mm tolerance requirements, with smooth, burr-free internal channels and minimized fluid resistance. The batch achieved a first-pass yield rate exceeding 98%, was delivered on schedule, and the client expressed high satisfaction with VMT’s precision machining

Q1: Is 6061 or 6063 easier to weld?

6063 aluminum is generally easier to weld than 6061 aluminum because it contains little to no copper, which significantly reduces the risk of hot cracking. In addition, its Mg–Si composition provides a more stable weld pool, resulting in smoother weld beads and more consistent weld quality.

Q2: Is 6063 aluminum bendable?

Yes. 6063 aluminum is highly bendable, especially in the T5 temper, where it offers good ductility and formability. This makes it well suited for bending and forming operations in extrusion-based components.

Q3: What about 6063 aluminum scrap?

6063 aluminum scrap has a stable recycling value and relatively low sorting requirements. Due to its widespread use and consistent alloy composition, it is a common material in secondary aluminum and recycling systems.

Q4: What forms does 6063 aluminum come in?

6063 aluminum is available in multiple standard and extruded forms, including 6063 aluminum tubing, 6063 aluminum pipe, 6063 aluminum plate, and a wide range of custom and standard extruded profiles designed for architectural and structural use.

Q5: What affects the 6063 aluminum price?

The price of 6063 aluminum is influenced by several factors, including the primary aluminum market price, heat treatment condition (such as T5 or T6), surface treatments like anodizing, and the complexity of the extrusion cross-section and machining precision required.

Q6: What is the equivalent of 6063 aluminum?

6063 aluminum is commonly equivalent to AA 6063 (USA), EN AW-6063 (Europe/Germany/UK/Norway), A6063 (Japan), and AD31 (Russia, GOST).